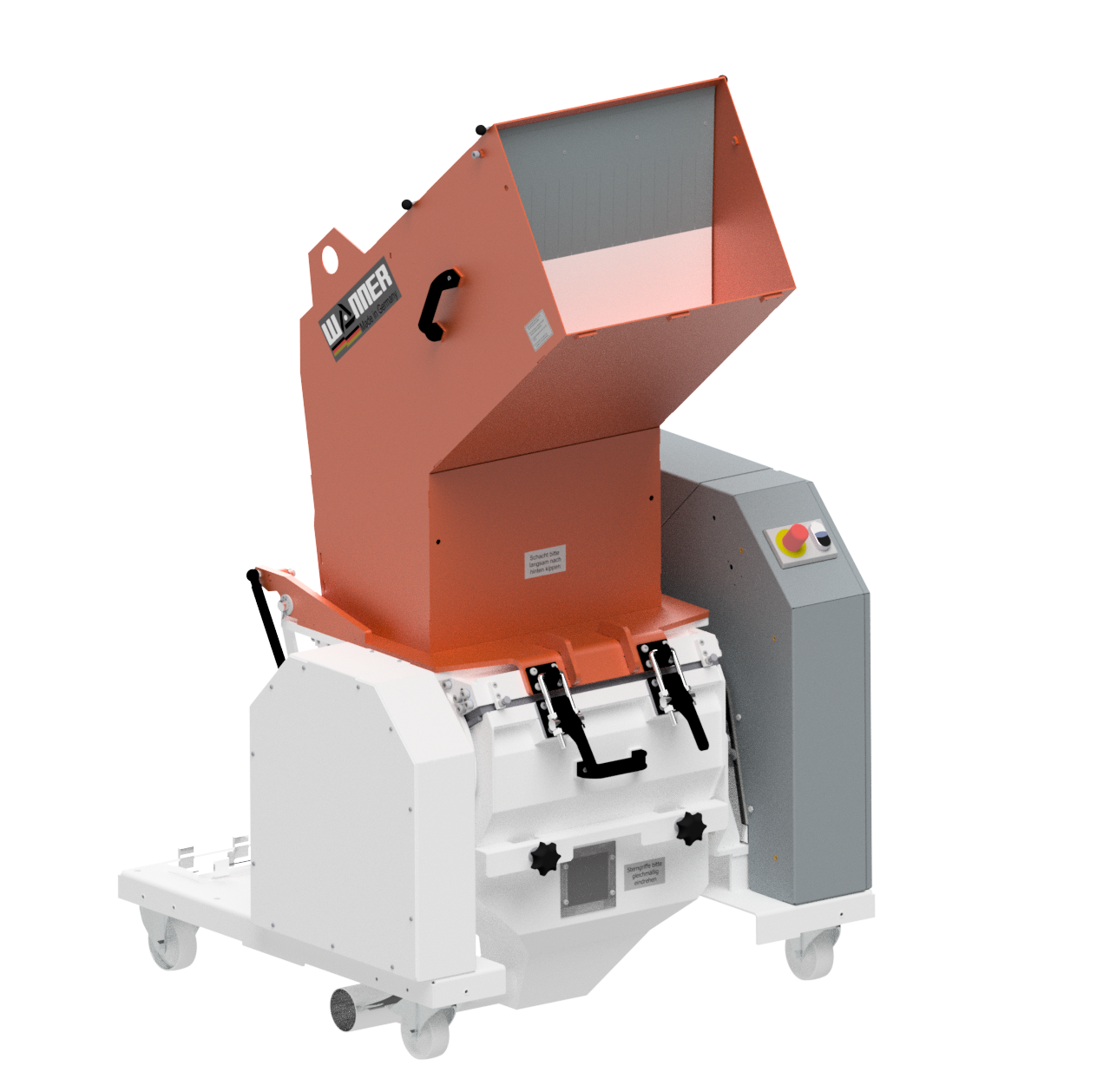

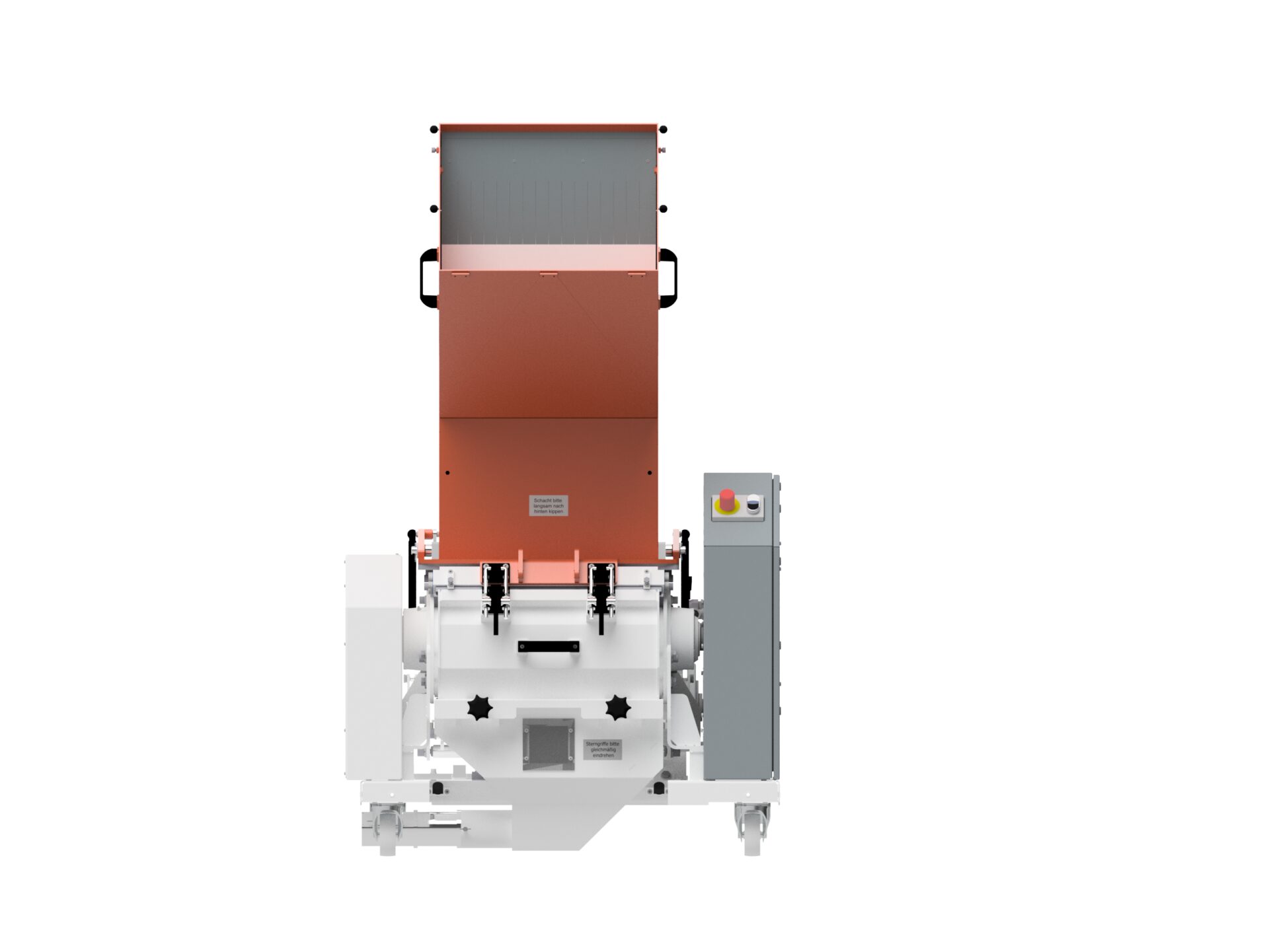

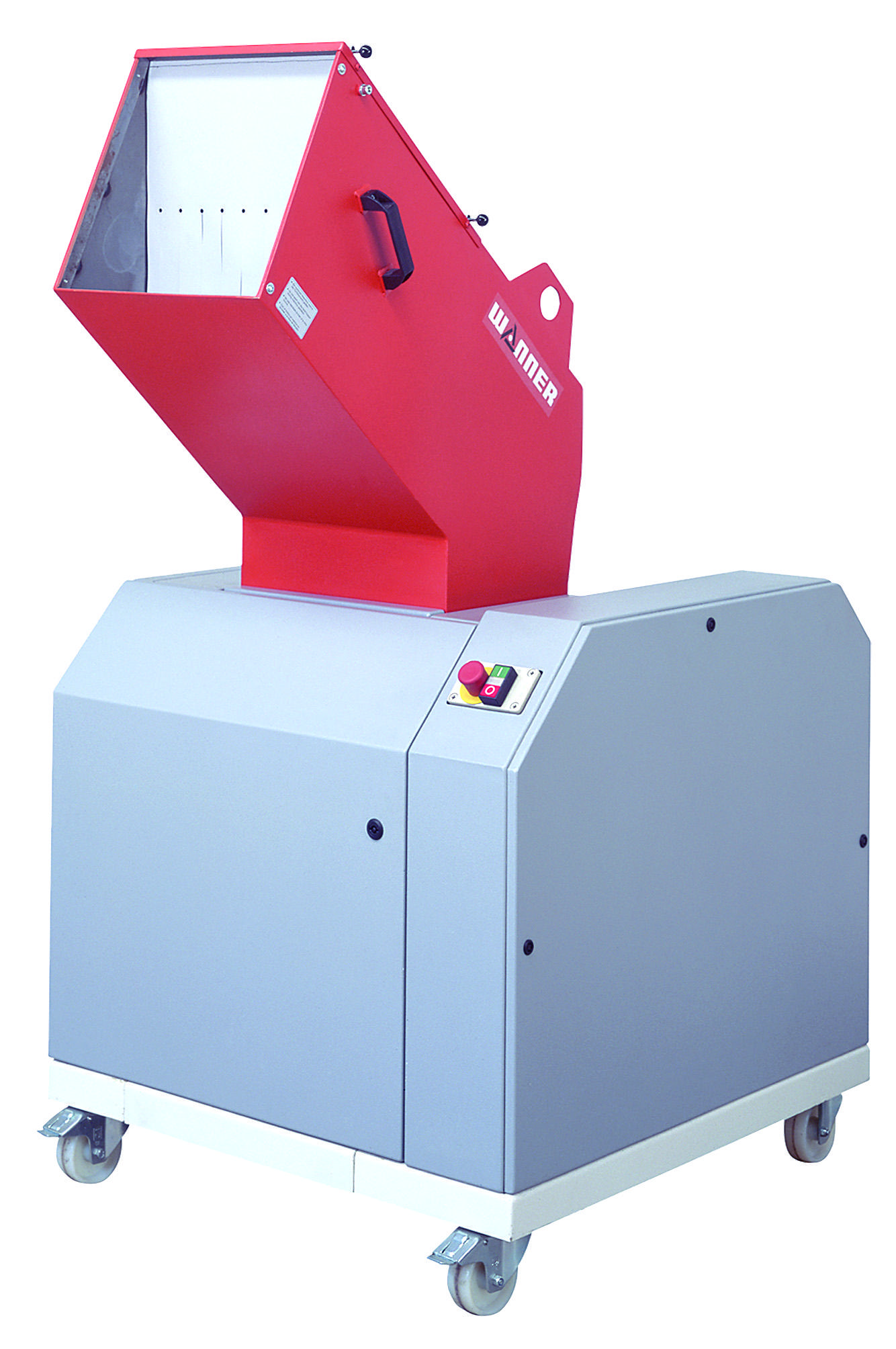

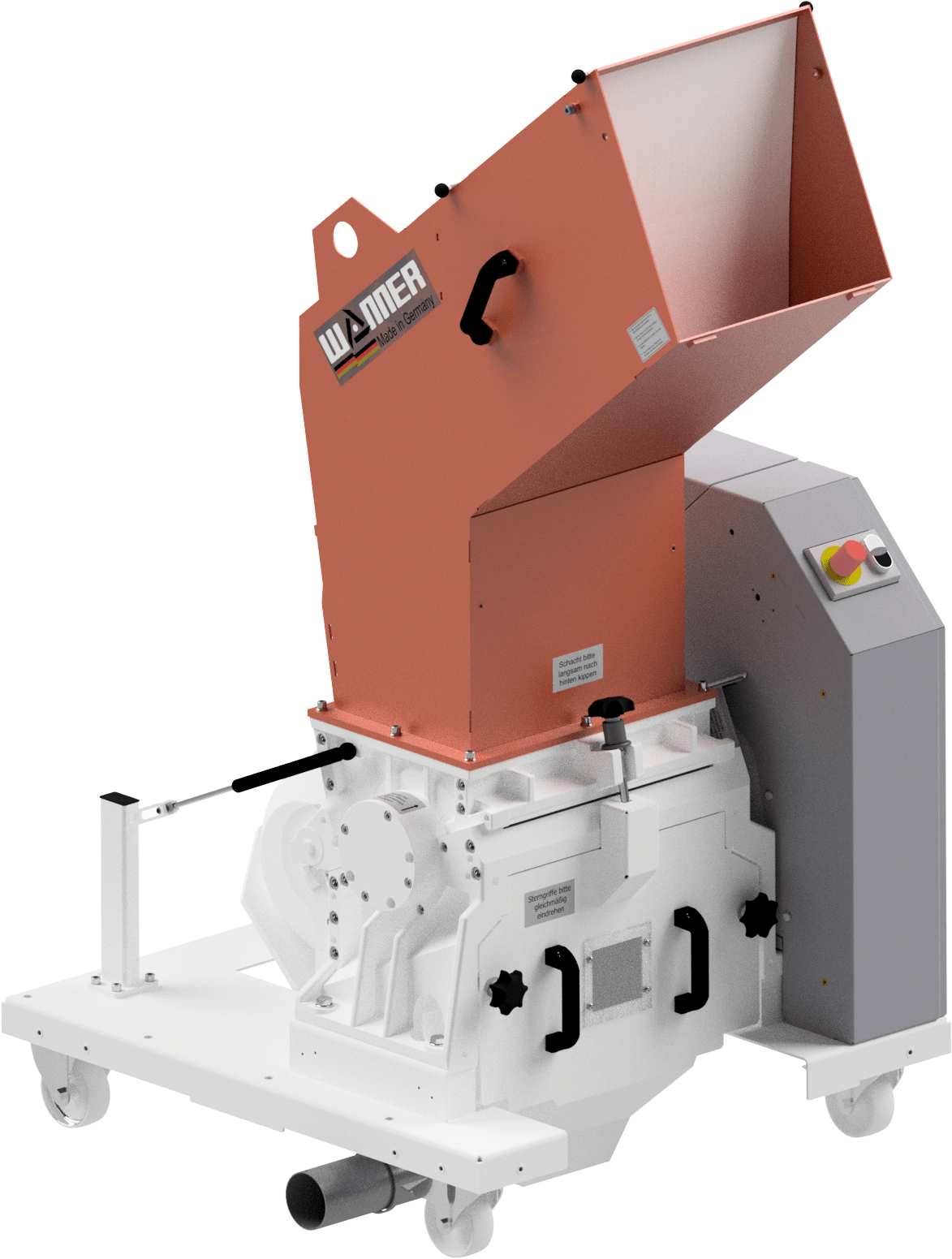

The robust universal grinder

The machines of the Dynamic series excel in their performance, whether they are used as a small, but efficient and robust central mill for technical plastics, or as an additional mill for large and massive sprues, side cavities or blowing waste.

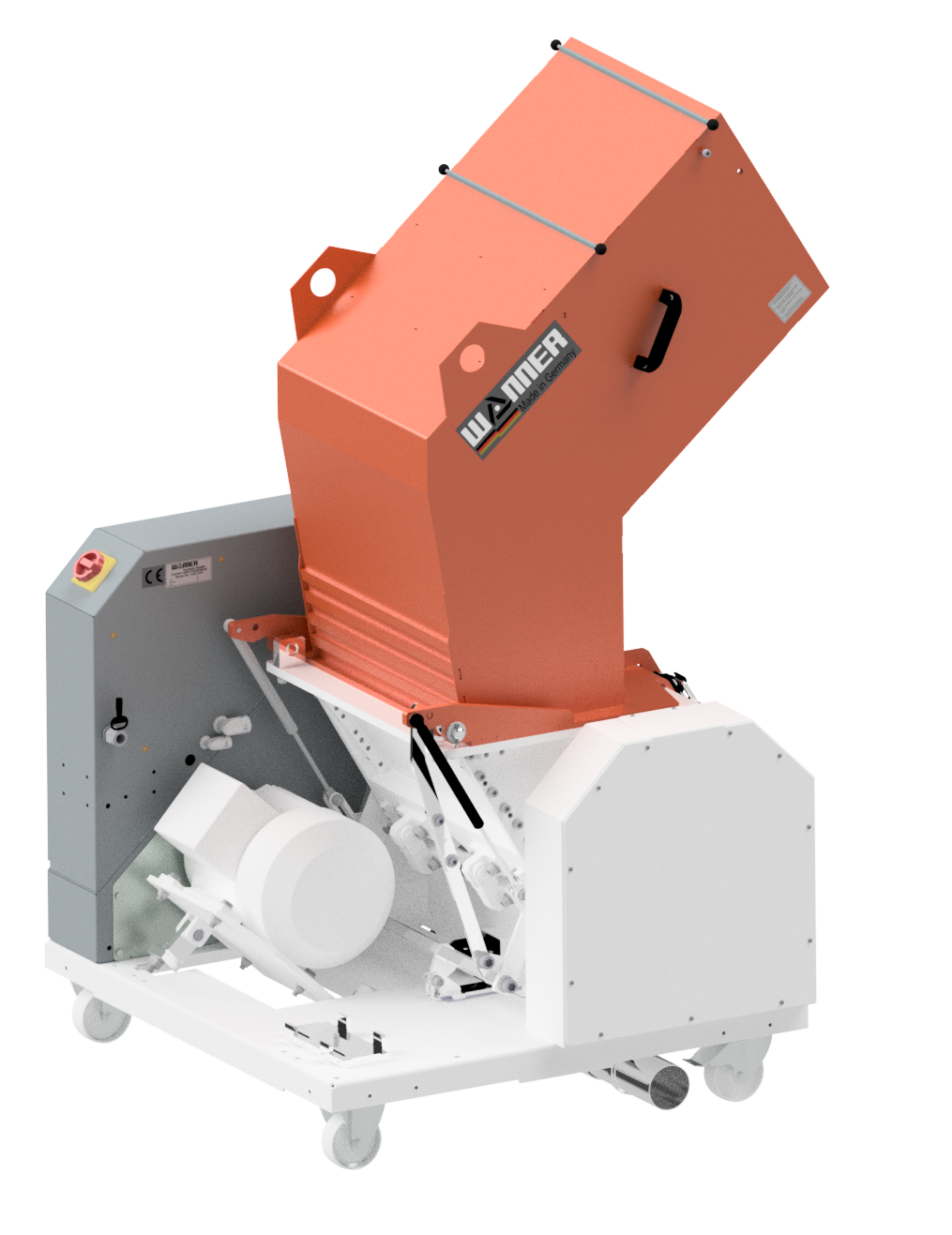

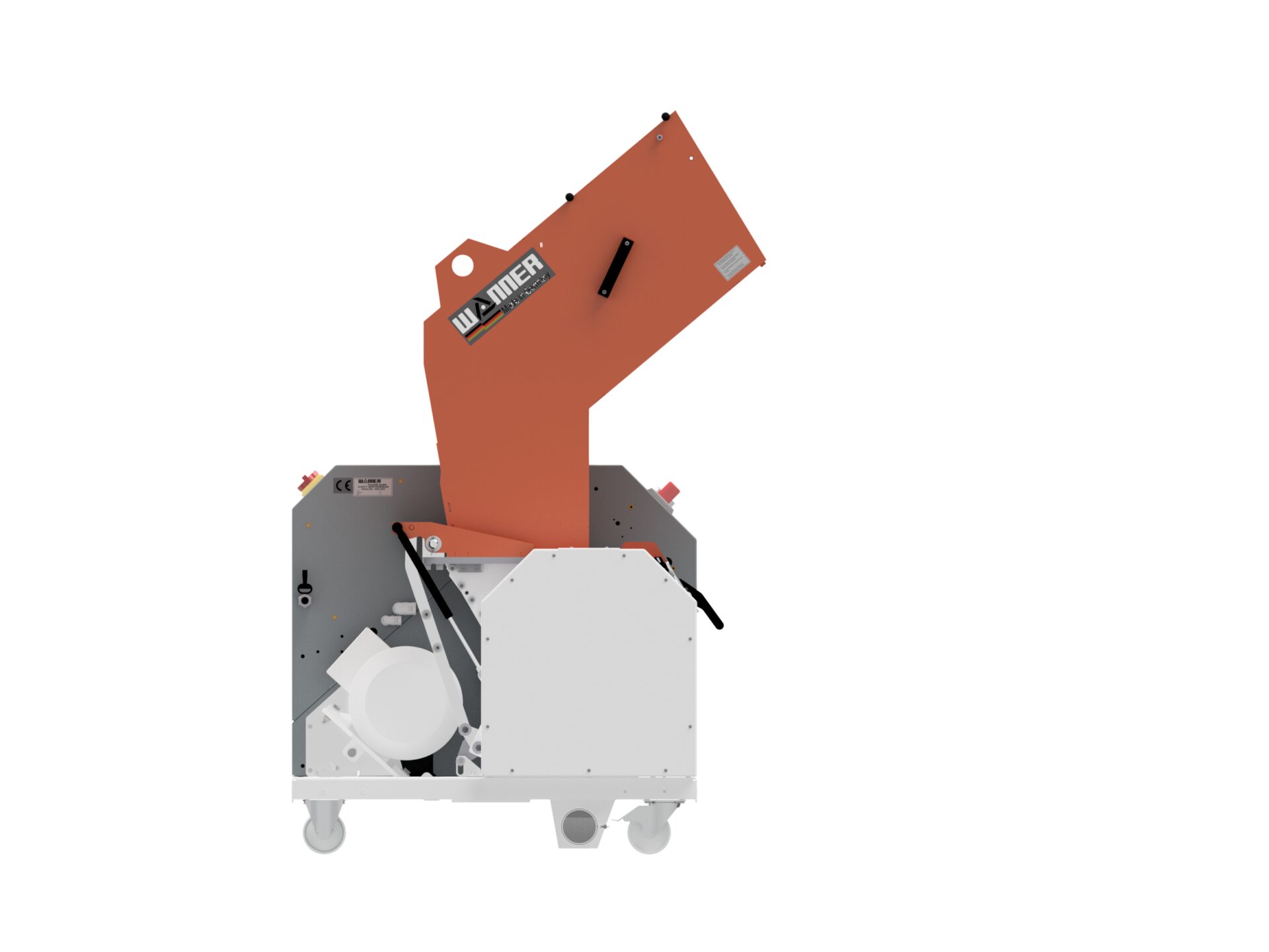

Thanks to the robust construction and the massive drive rod with a large flywheel mass, even exceptionally thick-walled parts such as solid housings made of tough plastics or extruded thick-walled plate segments can be ground just as well as, for example, large-mass blow molded waste or the associated large-volume bottles. The grinding chamber can be opened quickly and easily without tools. Cleaning is easy and takes little time, so material changes can be carried out quickly.

Even in the standard version, the grinding chamber is equipped with hardened wear-resistant components, so that even highly abrasive plastics can be ground without any problem. Thanks to the double-walled feed shaft, the noise level during grinding is considerably reduced. Thanks to the many options, the grinders can be configured to suit many different conditions.

- Large cutting chamber with hardened inserts guarantee reduced wear and thus a long service life, even when processing glass-filled materials.

- The rotor design allows for granulation of large parts and awkward sprue.

- Large cutting chamber and scissor action ensure low noise and good quality regrind with minimal penalties.

- Optional integrated soundproof housing.

- The controls range from simple contactor to comprehensive diagnostics.

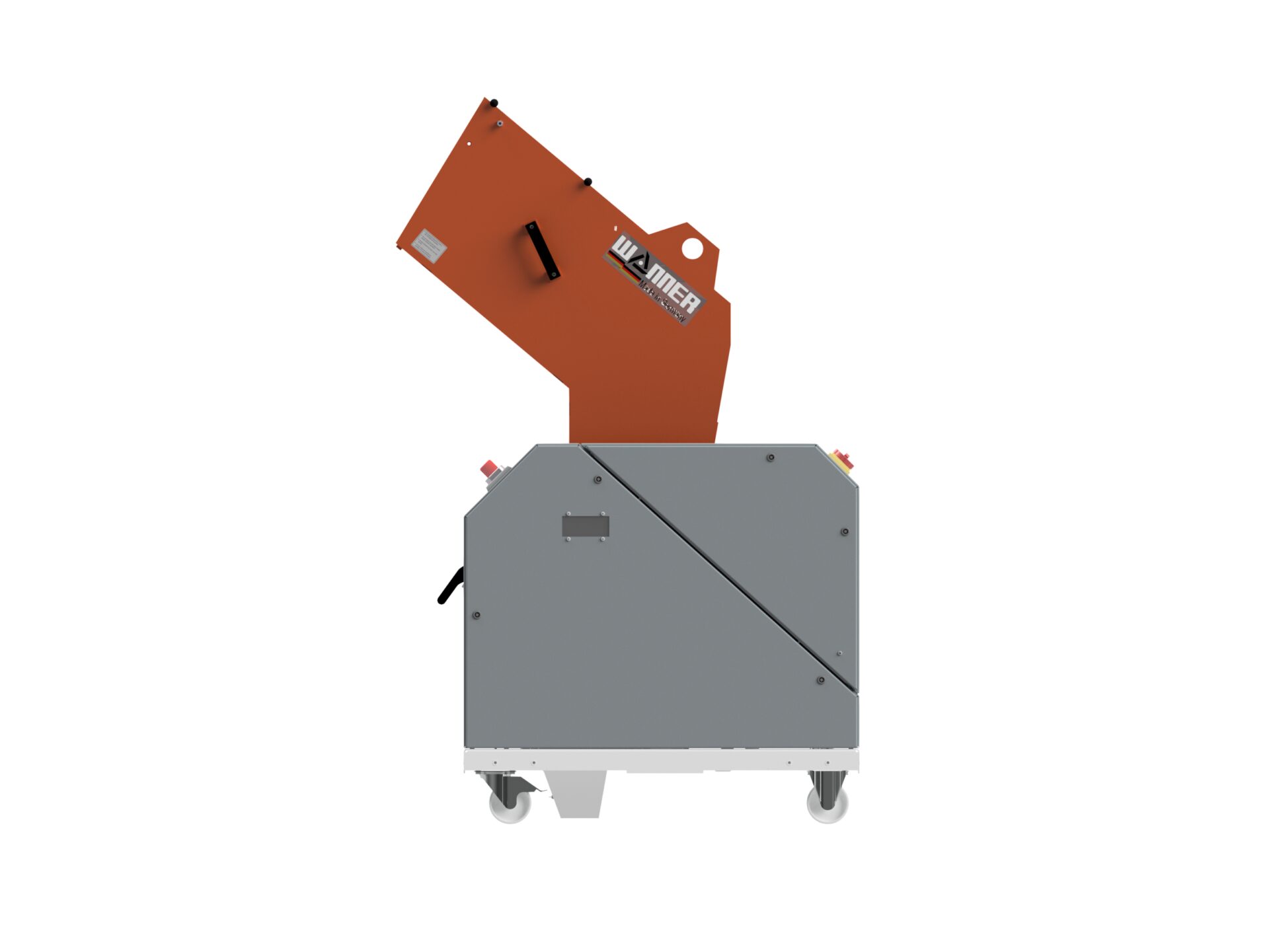

- Compact design and small footprint.

- Cutting blades are easy to re-sharpen.

- Tray for manual feed or robot feed hopper available

- Bag filling box for granulator on central granulating stand.

D-series granulators, with or without soundproof housing, are easy to open and provide full access to the cutting chamber for maintenance or cleaning. The sound-damping housing can be opened wide for easy access to the granulator. The cutting chamber can be opened very easily with no tools required, allowing excellent access and visibility to the rotor, screen and blades. Cleaning the granulator during a color or material change can therefore be done very easily.