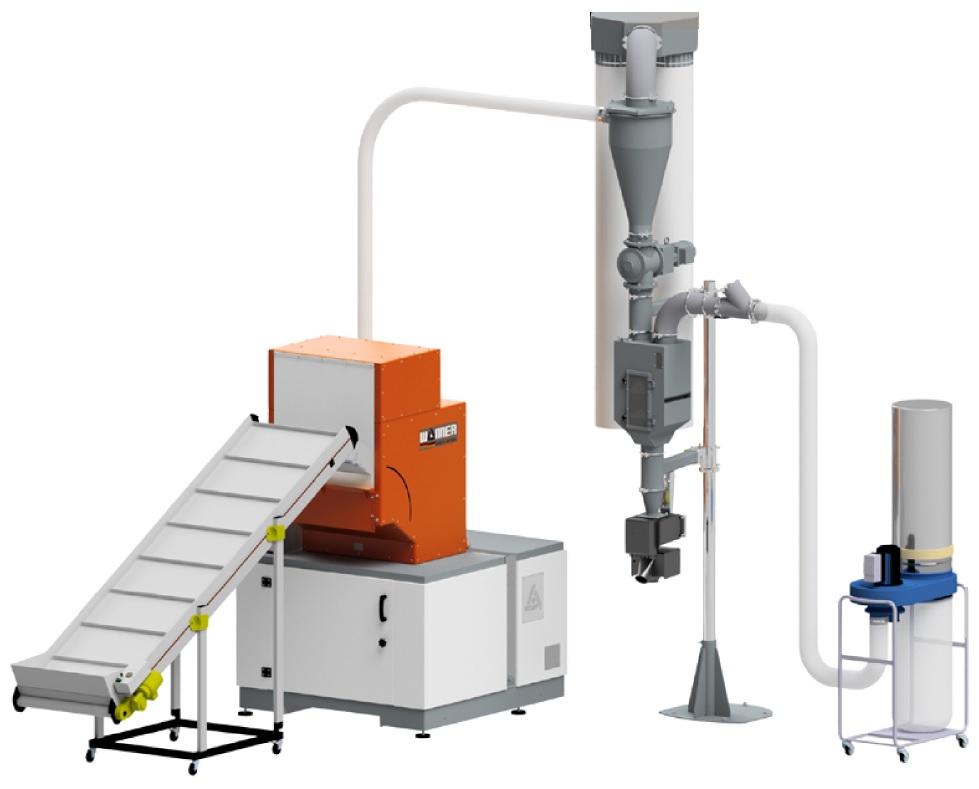

The Energy series

The grinder for large volume pieces

The ideal machine for grinding large-volume pieces, or for the central grinding of collected sprues or rejected pieces.

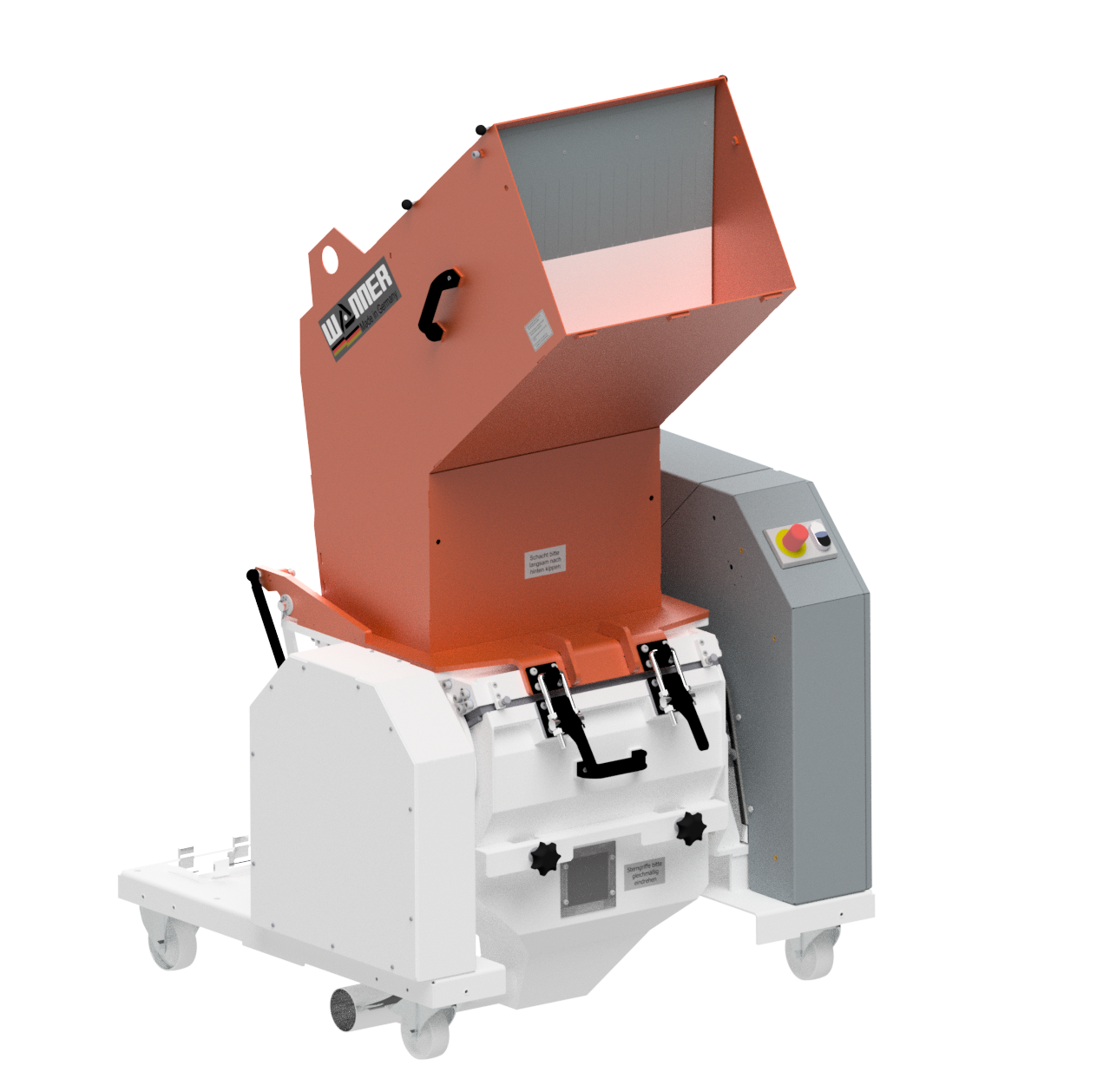

Thanks to the construction of the grinding chamber and of the rotors (which are constructed in such a way that they forcefully pull the pieces in), interlocking sprues, or bulky pieces (such as barrels, bottles, boxes or trays) are gripped and inside evenly and quickly drawn.

The mills are standard equipped with an integrated soundproof housing, which efficiently reduces the noise level. The grinding chamber with associated drive unit is disconnected from the mill chassis by means of anti-vibration elements, so that contact noises are effectively suppressed. The grinding chamber can be opened quickly and easily with just a few actions and completely without tools, so that it can be easily cleaned.

The many options available make it possible to adapt the grinder to the customer’s requirements. As a result, a complete grinding installation can be built up cheaply, with periphery (for example with dust separation and material supply).

- Standard soundproof enclosure for a low noise level.

- Easy access to the integrated, silenced fan for cleaning.

- Partially clamped welded steel cutting chamber, for minimal vibration.

- Rubber supports isolate the cutting chamber and motor from the base frame and hopper for reduced vibration and noise.

- Cutting chamber with tangential entry for easy entry of bulky rejects.

- Extra large bearings, shafts and drive guarantee a long service life.

- A choice of rotor geometries to suit your application. Standard scissor or V-cut configuration for high-quality, low-dust granulate.

- Small footprint achieved through compact design. Optional caster wheels for easy mobility.

- Quick and easy tool-less access to cutting chamber for material or color change.

- Additional interface options for controlling associated auxiliary equipment.

- System components such as material infeed belt, metal detector, metal separator, granulate removal and dust removal units for the complete recycling package.

- Easily accessible cutting chamber, motor and blower through large doors in the sound-absorbing housing.