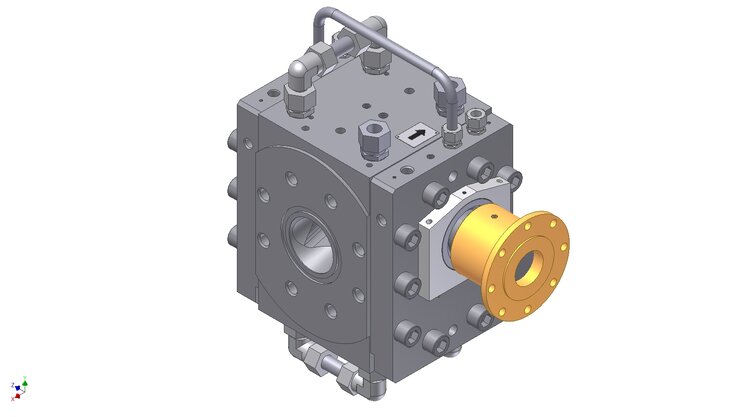

Eprotec for efficient and reliable melt pump solutions in the world of extrusion!

From engineering to commissioning melting pumps of the highest Swiss quality and precision.

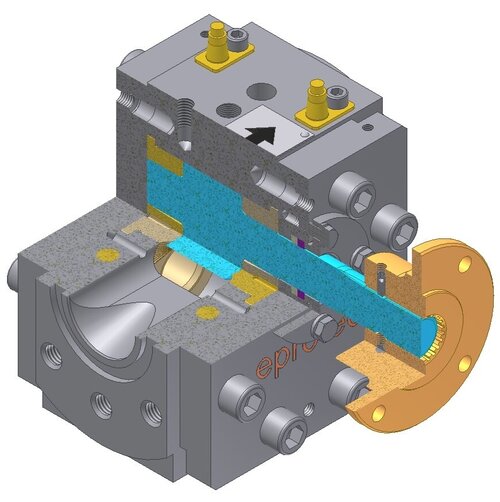

The Eprotec melt pump optimizes the extrusion process by relieving pressure build-up on the extrusion screw, thus improving homogenization.

In extrusion applications, gear pumps (melt pumps) stabilize the process by generating constant pressure, ensuring constant material flow and relieving pressure build-up on the extruder.

This reduces the shear, optimizes the melting process and reduces the extruder power consumption. consumption. consumption.

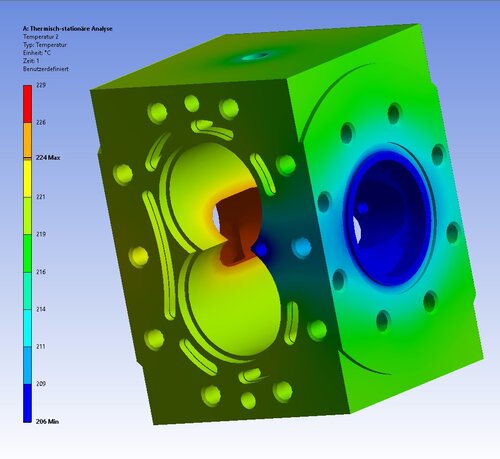

Eprotec melt-X melting pumps are always state of the art and are synonymous with precision, durability and innovation.

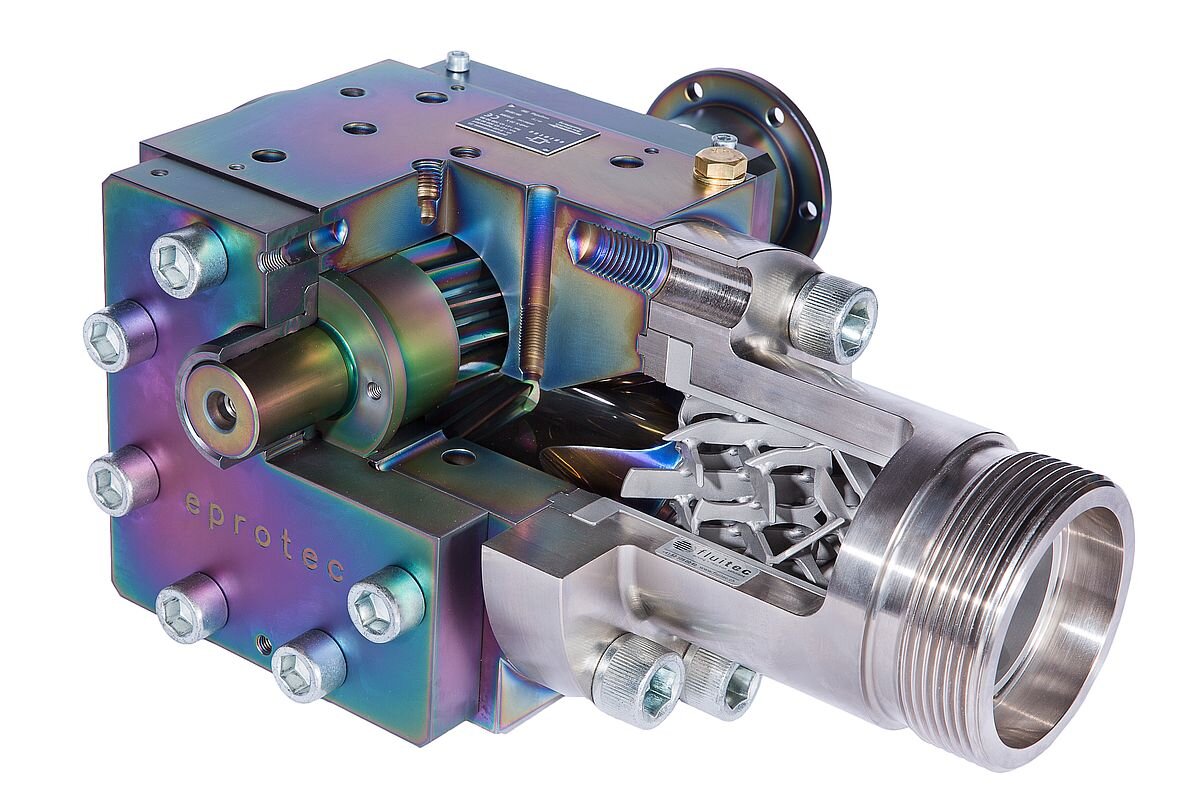

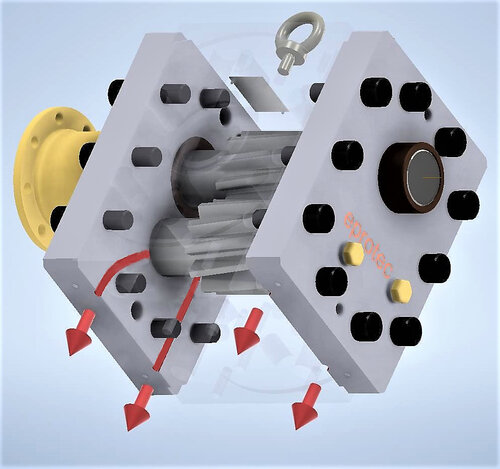

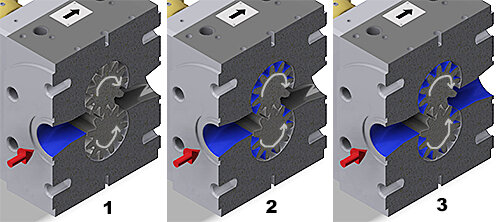

Operation:

- The volumetric pumping unit has two externally toothed gears that interlock when turning. A small pressure in the pump inlet is sufficient to fill the tooth chambers.

- On the discharge side, the interlocking of the gear teeth drains the melt from the tooth chamber.

- Two slide bearings per gear shaft absorb the forces. They are lubricated by the polymer and are maintenance free.

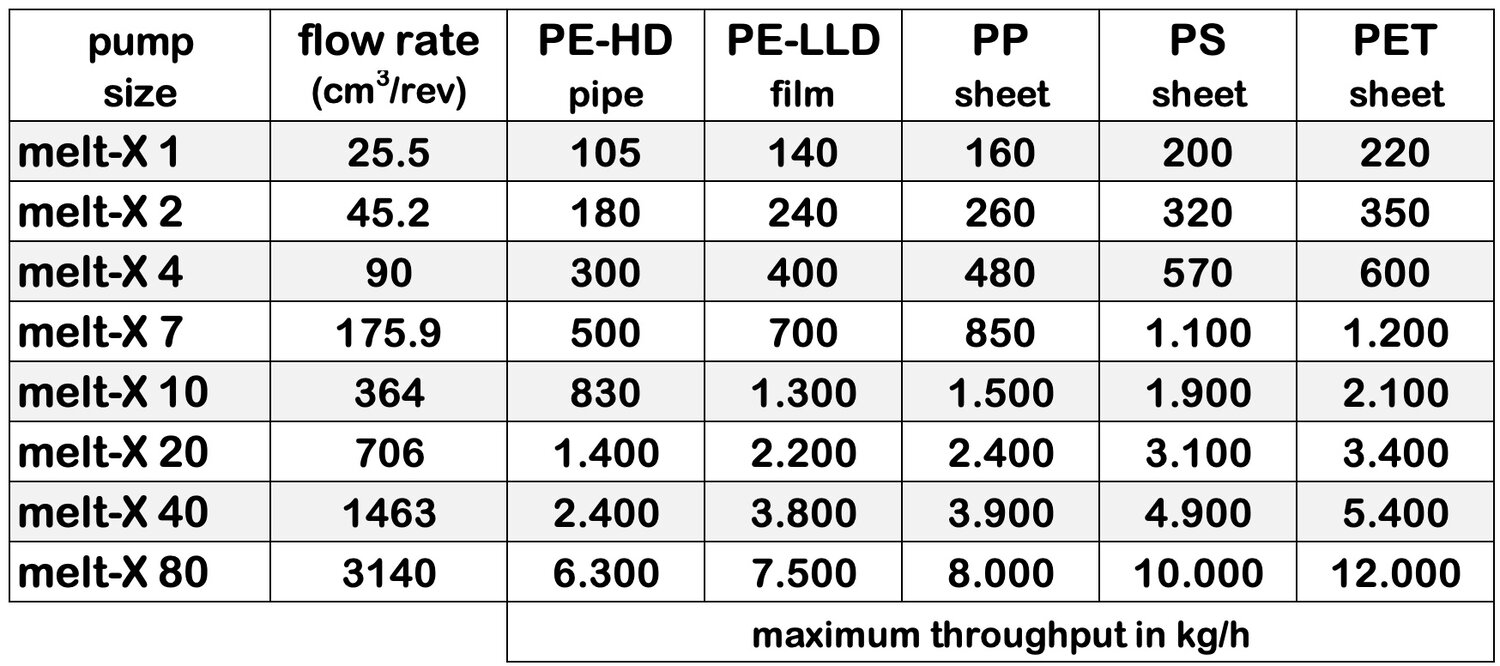

- For recycling, compounding, film, sheets,…

- Throughput up to 8,000 kg/h.

- Reduction of extruder pressure by shifting pressure build-up to the gear pump.

- Increase throughput, leading to maximum production efficiency

- Elimination of output variations and pressure pulsations, improving product quality

- Savings on raw materials through tighter production tolerances

- Reduction of product rejection by eliminating pulsations in the process

- Improving dimensional accuracy in sheet and profile production

- Optimization of surface and optical quality in the production of films, sheets and profiles

- Higher product quality in homogeneity and grain size in preparation applications Imperial US joint geometry