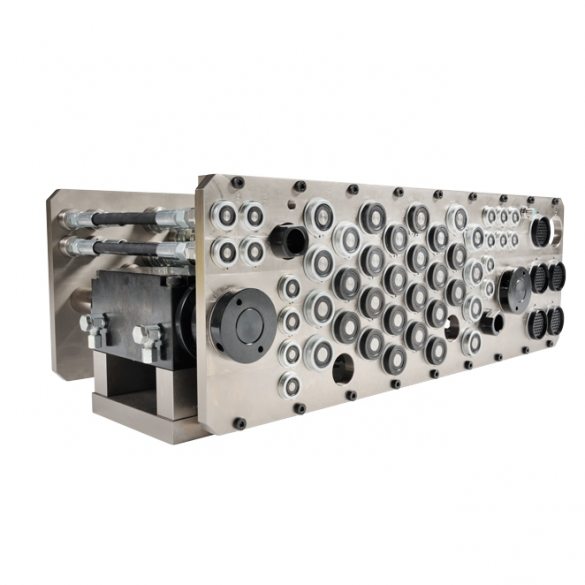

EAS automatic multi-couplers are used for a wide range of industrial applications requiring water, air, steam, hydraulic and electrical connections. Because coupling and uncoupling takes place automatically via hydraulic or pneumatic cylinders, everything is connected directly and incorrect connection is prevented.

Automatic Multi-Couplings

The EAS automatic multi-couplers feature unique, flat, self-locking mono-couplings for water, air, hydraulic and steam connections. Both halves of the multi-coupling are held together by the individual mono-couplings.

KEY FEATURES AUTOMATIC MULTI-LINKS

- Flat, leak-free mono couplings

- Self-locking mono couplers – no expensive systems needed to secure the two halves of the coupler

- Equipped with inductive sensors for the extended and retracted position.

- Suitable for 1 to 300 mono couplers or more

- Mono couplings available from size 6 to size 45 and up to 1500 l/min and 30 bar for water and hydraulic connections up to 200 bar

- Special couplings available for applications with residual pressure in the system.

APPLICATIONS

Used in more advanced mold quick change systems in injection molding machines, where connections for water cooling, oil heating and electricity and hydraulic connections for core drawing are made automatically. In blow molding machines for water cooling connections, test benches for car engines, in the machine building industry, such as multi-couplers for pallets on CNC machines, for the connection of a moving bolster on larger stamping machines, for sheet metal rolling and in the aerospace industry.