An electropermanent magnetic clamping system offers mold manufacturers who cannot standardize their molds flexible clamping options.

PRESSMAG SP: MORE FLEXIBILITY ON SMALLER MACHINES

No mold standardization required with SP clamping systems from EAS. Like all EAS magnetic clamping solutions, the SP does not require an electrical current to hold tension.

- higher tension force;

- thinner plates;

- flexible around holes = more tension;

- max. number of fixing bolts = no air gap;

- standard temperature range up to 150 °C.

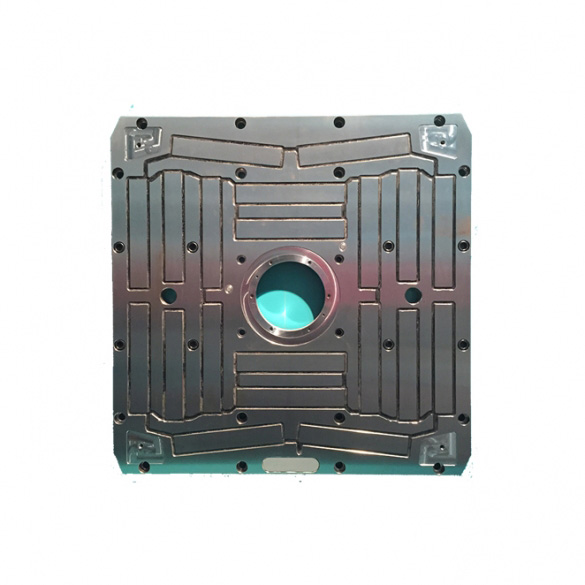

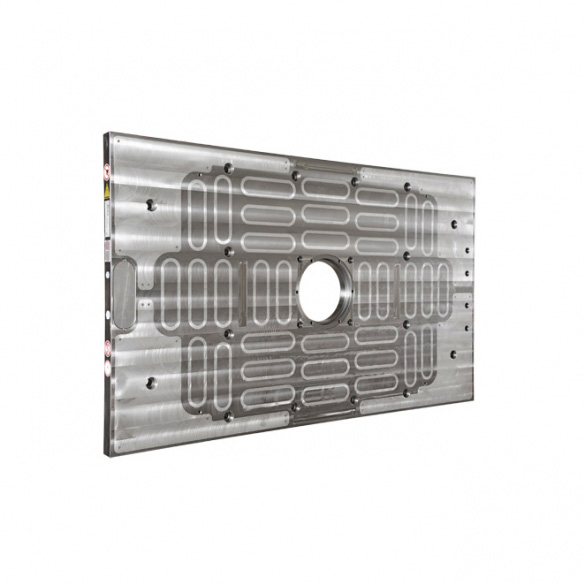

Smaller poles that deliver more power

Pressmag SP electropermanent magnetic systems have a 47mm square base and pole-to-pole design with alternating north-south poles. This gives more tension around

the center of the clamping tables of small machines.

47mm poles fit more easily between and around openings than larger poles.

More small poles = more power than larger poles.

Resin seal or metal-to-metal surface

The Pressmag SP100 is designed for a maximum temperature of 100 ºC and has square poles with resin sealing.

The Pressmag SP150 has laser-cut stainless steel seals and the system is covered with an easy-to-clean, perfectly flat steel surface.

The Pressmag SP150 is designed for use at high temperatures up to 150 ºC.

Magnetic plate does not bend

To maintain the hardness of the SP’s plate, EAS adds screws between the poles and around the center.

PRESS MAGS AND TEMPERATURE

Magnets are affected by temperature. Below you can see the different operating temperatures for each Pressmag system:

| Press mag type | machine size | Operating temperature |

| SP100 | < 400 tons | 100°C (212°F) |

| SP150 | < 400 tons | 150°C (302°F) |

| HP100 | > 400 tons | 100°C (212°F) |

| HP120 | > 400 tons | 120°C (248°F) |

| LP100 | > 400 tons | 100°C (212°F) |

|

|

| Pressmag SP electropermanent magnetic systems have a 47mm square base and pole-to-pole design with alternating north-south poles. This gives more clamping force around the center of the clamping tables of small machines. | Pressmag SP installed on the IMM |

|

|

| The Pressmag SP150 |