- Side entry robots make it possible to solve certain problems that can arise with plastic injection molding that cannot be done with traditional robots.

- In particular, the SideFast CNC model allows very fast cycles (up to 3 seconds for the total cycle): this is typical of the packaging industry where the pieces have very small thicknesses.

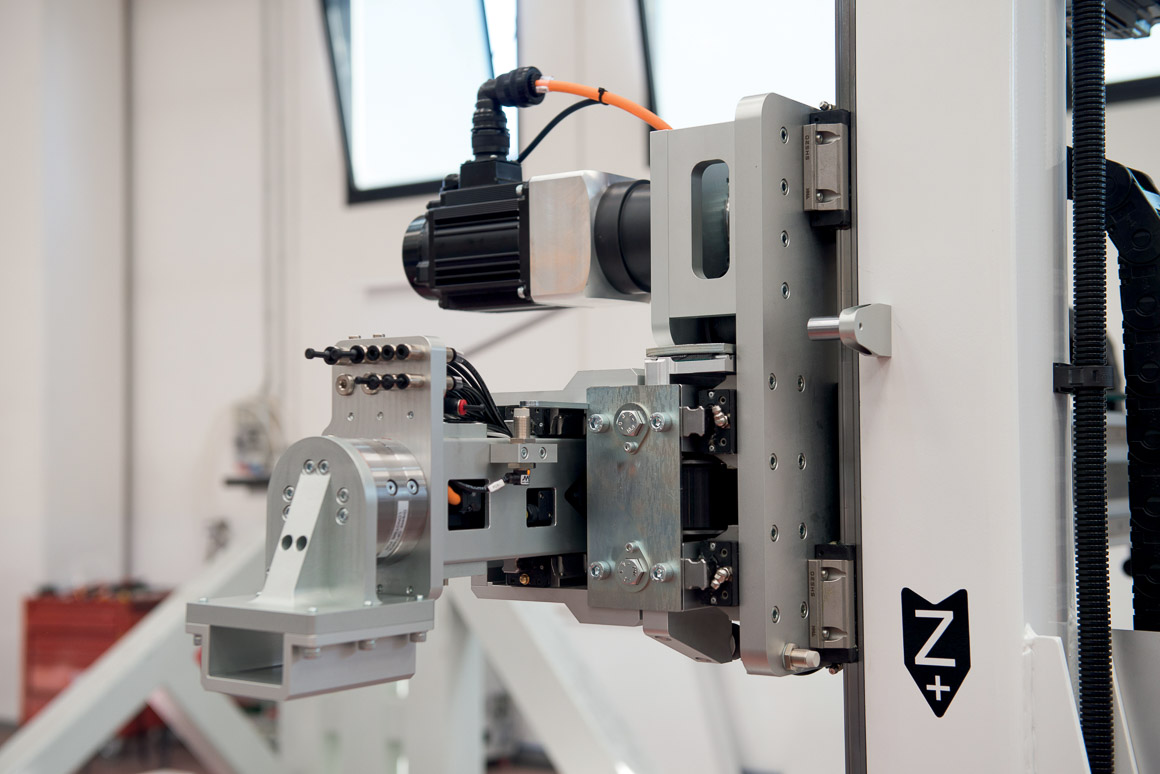

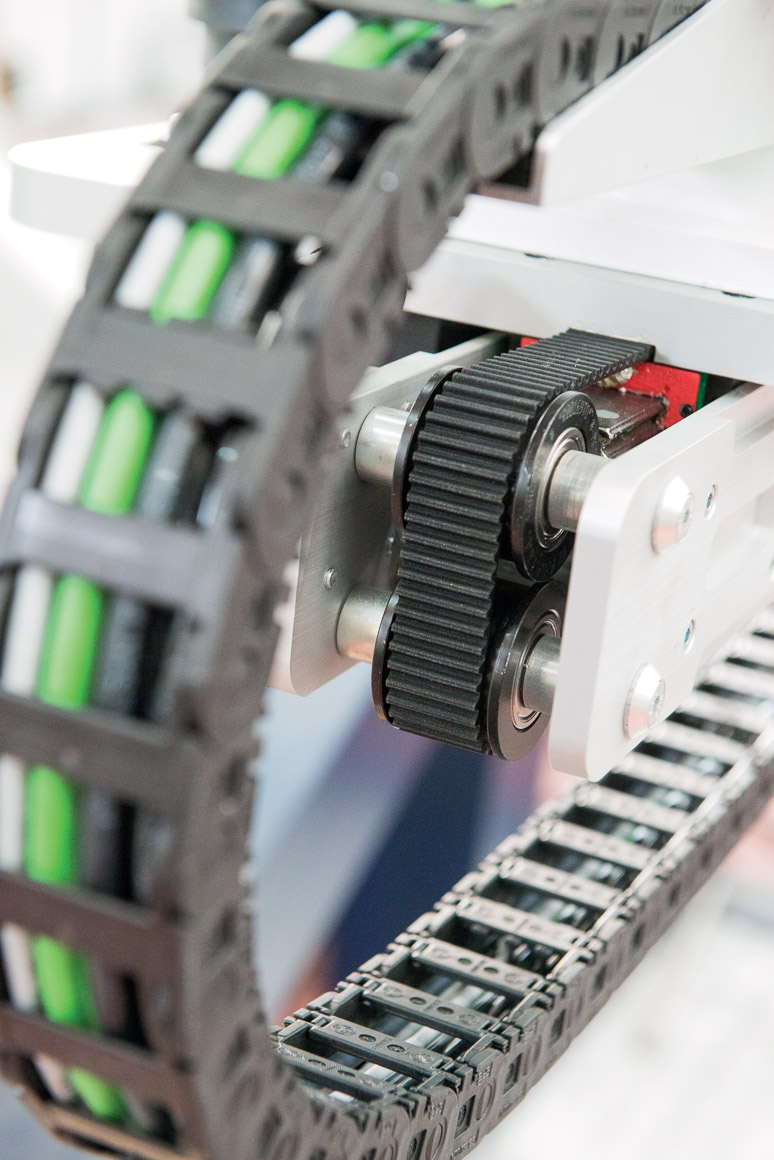

- Very powerful motors and the special structure make it possible to achieve very short cycle times.

- In some cases, this model can also be used to place labels in the mold using “IML” technology.

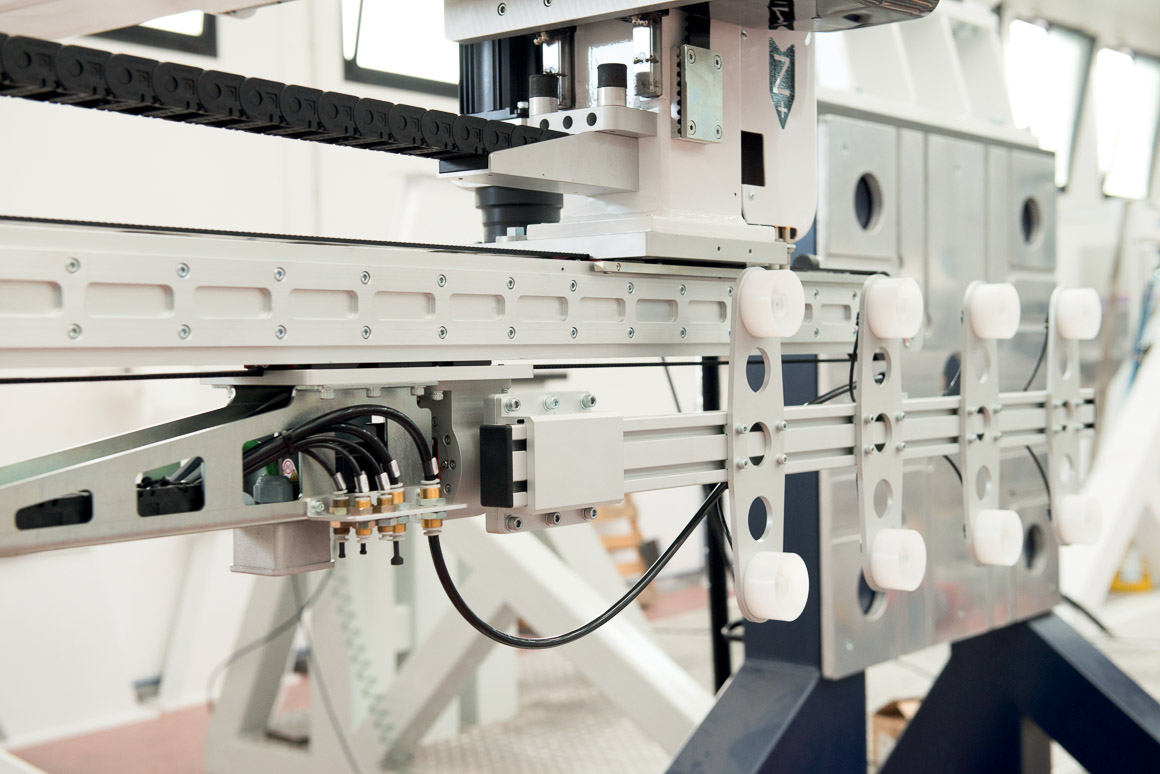

- The inlet shaft in the mold is telescopic to reduce dimensions and achieve high speeds.

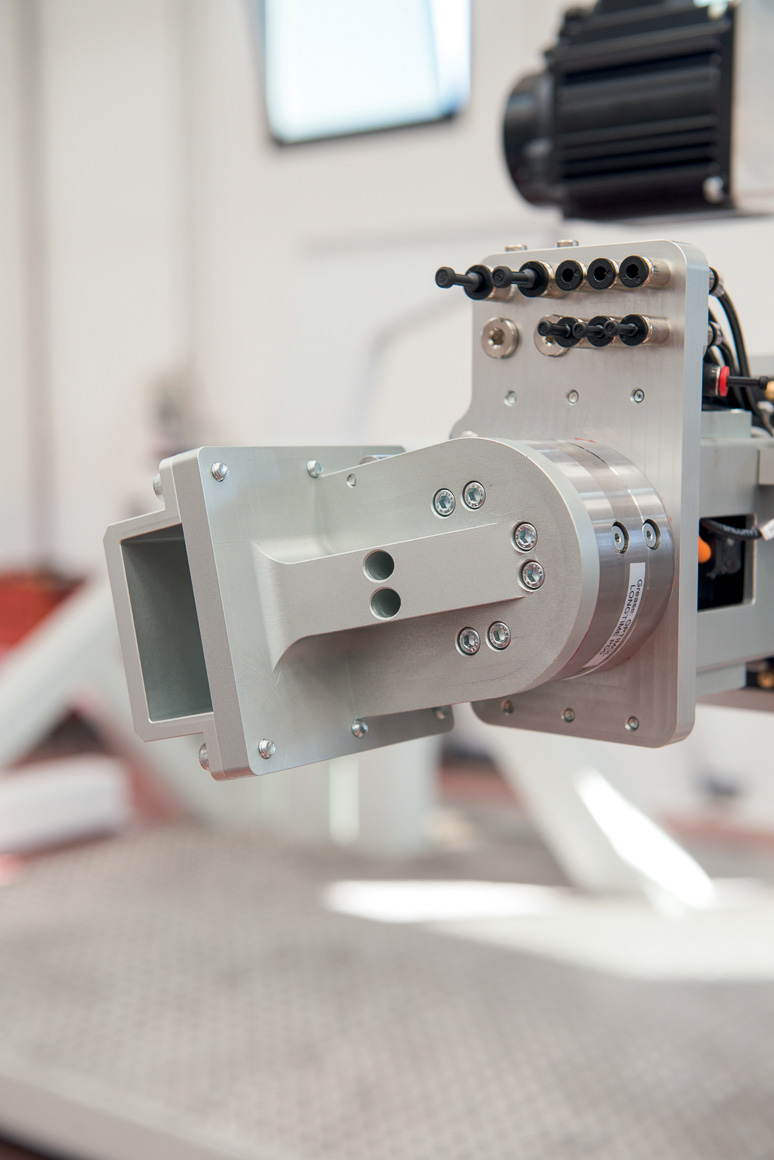

- The removal hand is rotated by a brushless servo motor. The installation of this robot can be done both by fixing it to the fixed side of the press and by fixing it to the ground, detached from the press.

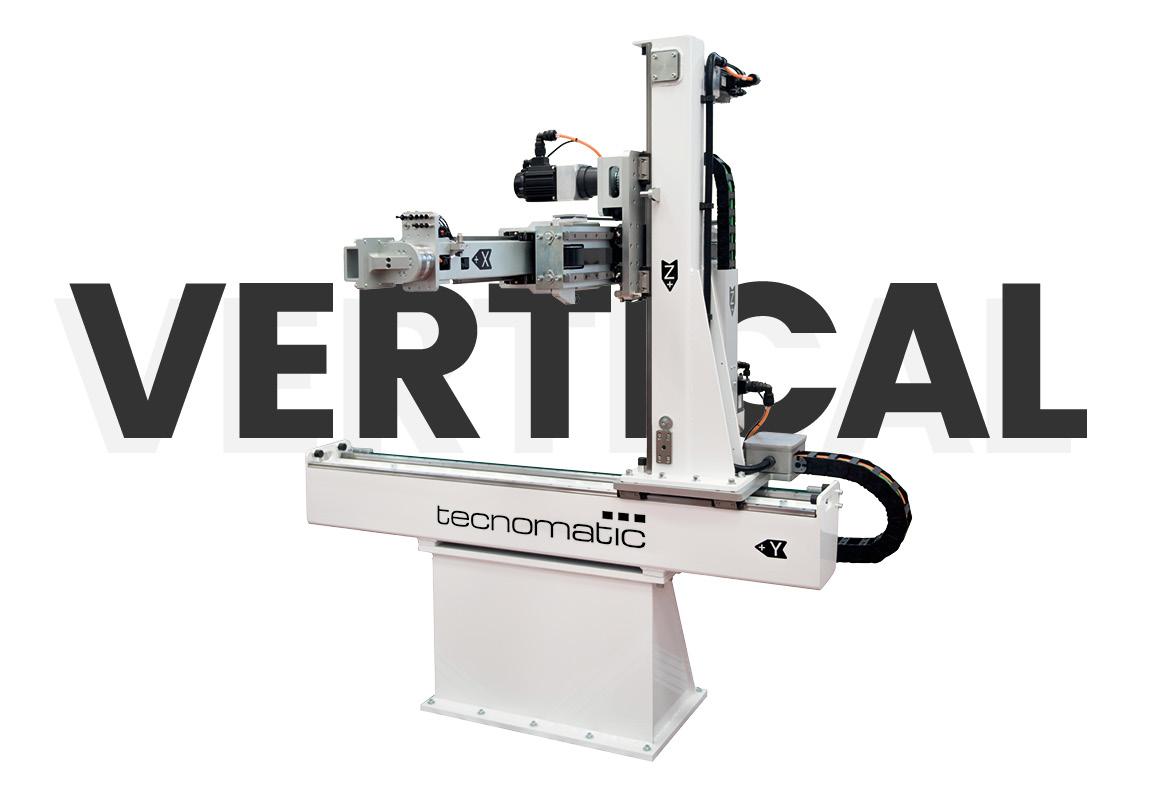

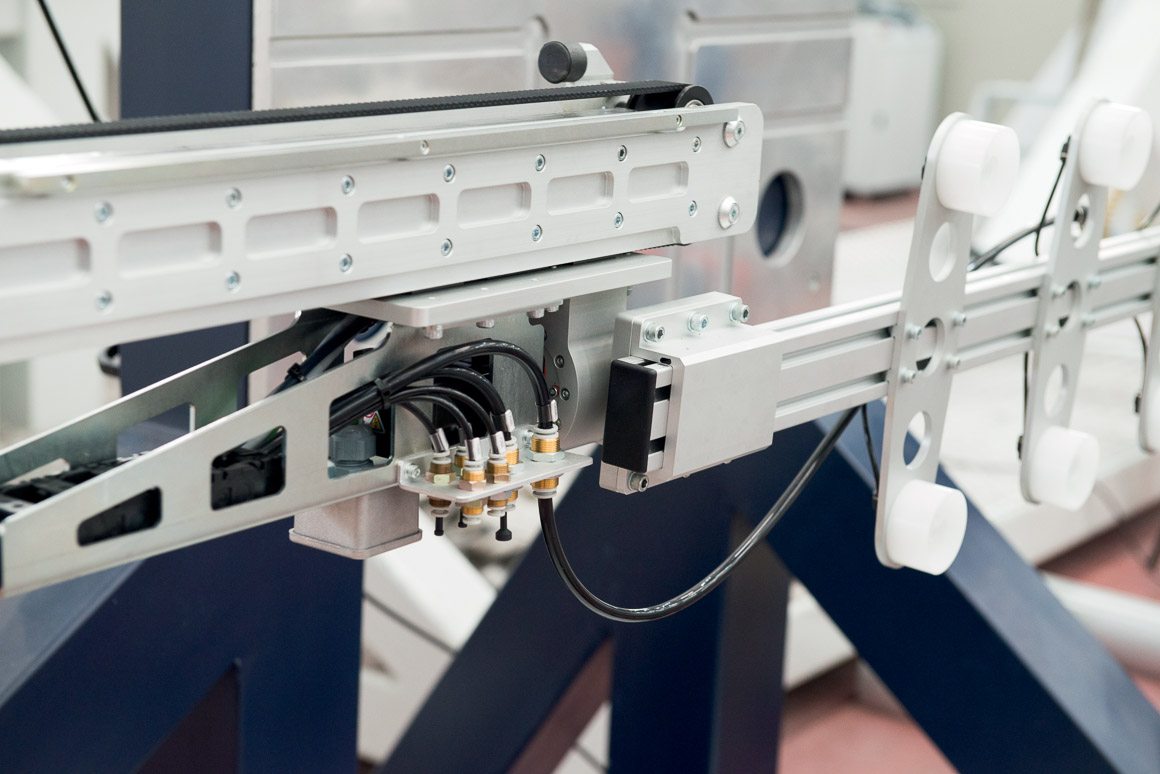

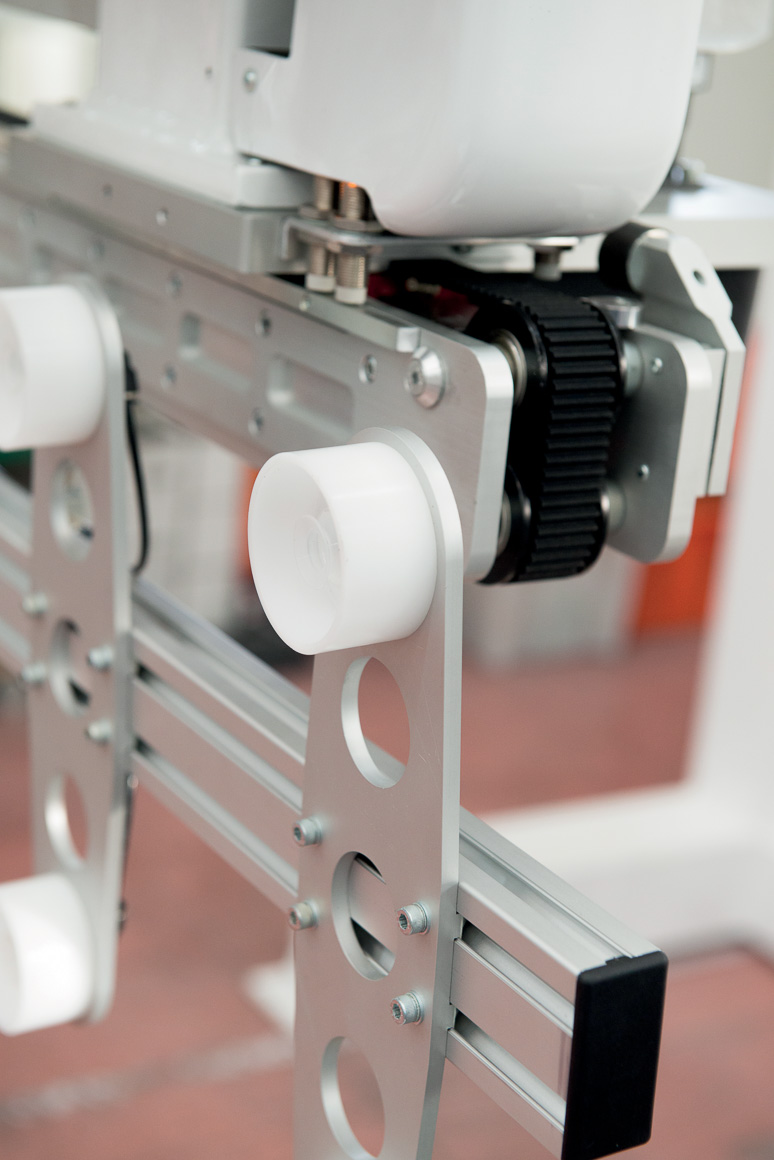

- The vertical CNC is used in cases where the available height in the factory is very limited and does not allow a robot to be installed in the usual position (above the fixed side).

- It is placed next to the press and fixed to the floor.

- The inlet shaft in the mold is telescopic to reduce dimensions.

- The wrist is rotated by a brushless servo motor.

- Another application of this robot is for use in vertical presses.

- We also design special versions of side entry robots to customer specifications, both for complex IML systems and for use in “clean rooms”.

PROGRAMMING

- Free Guided Programming (FGP) that allows work programs to be written using “actions” already written and contained in a special library;

- Self-learning of positions related to the axis movements;

- Step-by-step and low-speed execution of the program to check the accuracy;

- Programs can be stored on a USB drive;

- Ability to perform work cycles consisting of any sequence of motion;

- Numerous workpiece pelletizing and depalletizing schemes for filling pallets, cartons, etc.;

- It is possible to enter in the main program different types of sub-programs that will be executed on demand or when the pre-set conditions arise (for example, to discard defective pieces, insert cardboard reinforcements, etc.);

- It is possible to demould parts with undercut.

| Fashion model | side fast | vertical |

| IMM (tons) | 150-450 | 200-700 |

| std. Strokes X (telescopic) Y (longitudinal) Z (vertical) |

X= 1630mm | X= 1620mm |

| Y= 400mm | Y= 1200mm | |

| Z= 600mm | Z= 670mm | |

| Max applicability & weight | 6 | 8 |

| min. cycle time | 3.5 sec | 7 sec |

| Wrist rotation | Servo 0-360° | Servo 0-360° |

| power supply | 400V three phase | 400V three phase |

- Very fast cycles possible

- Special versions of side entry robots according to customer specifications are also possible