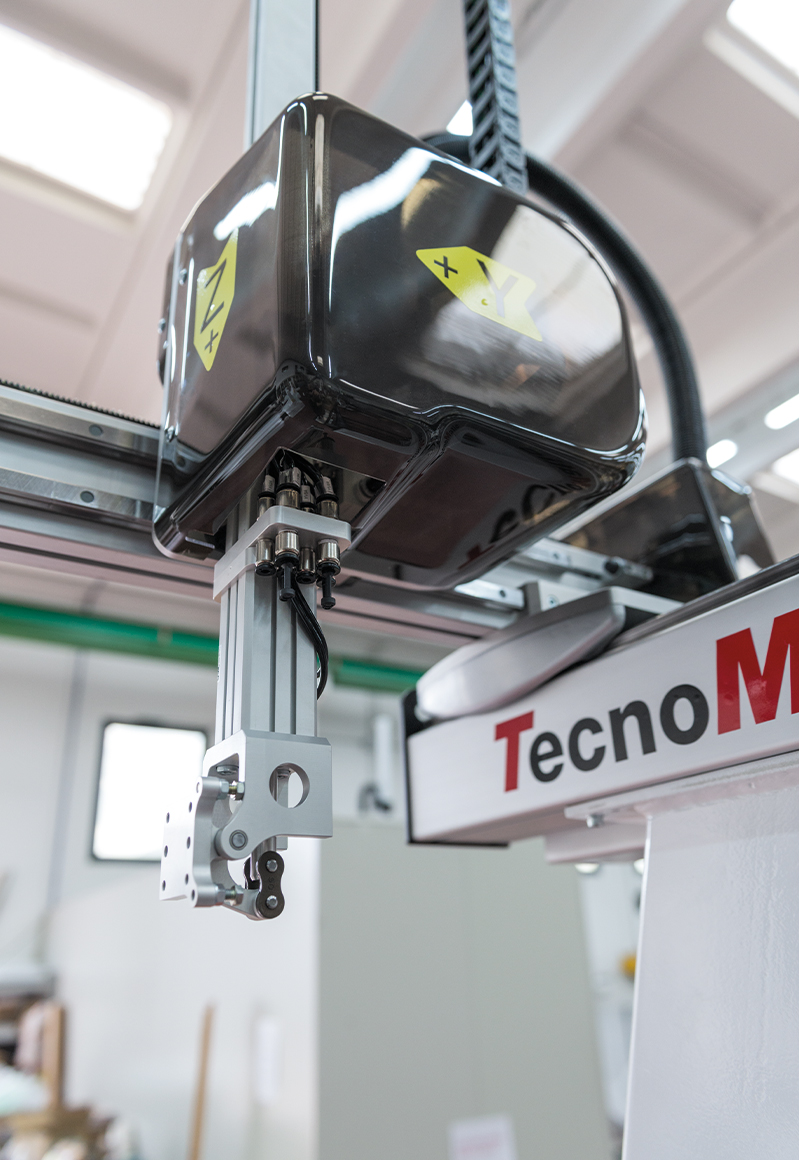

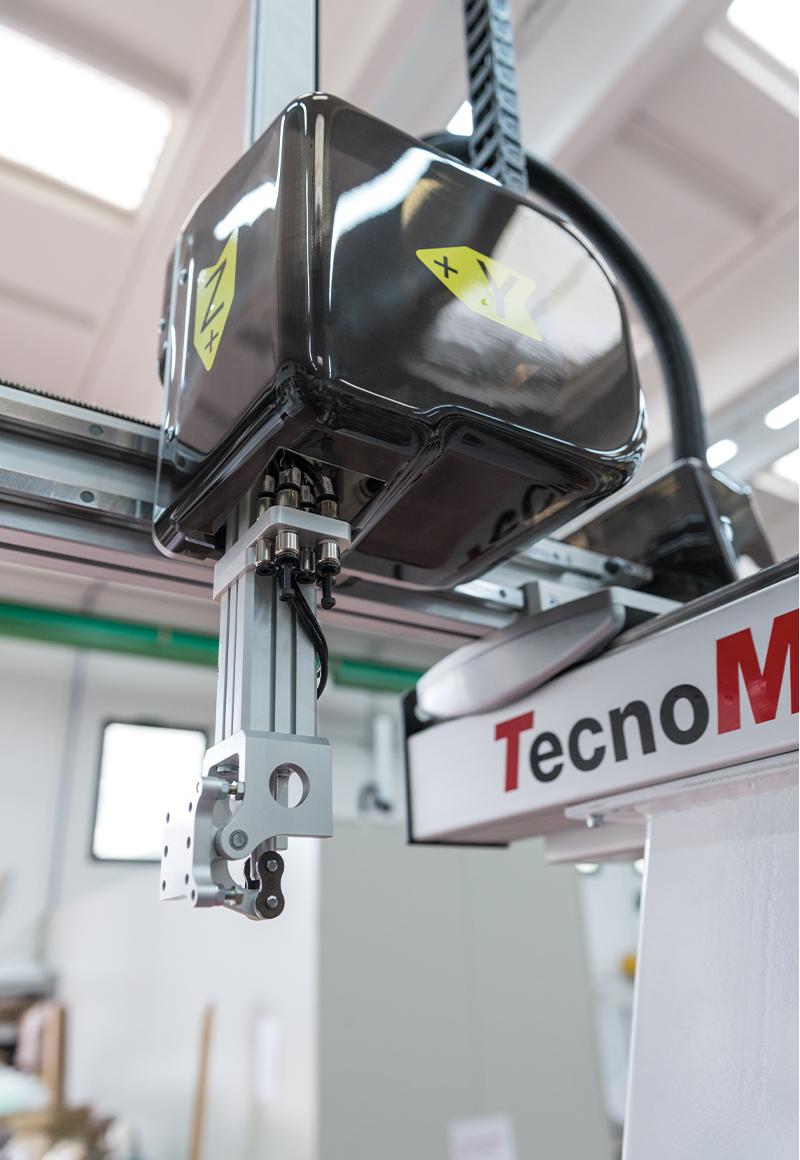

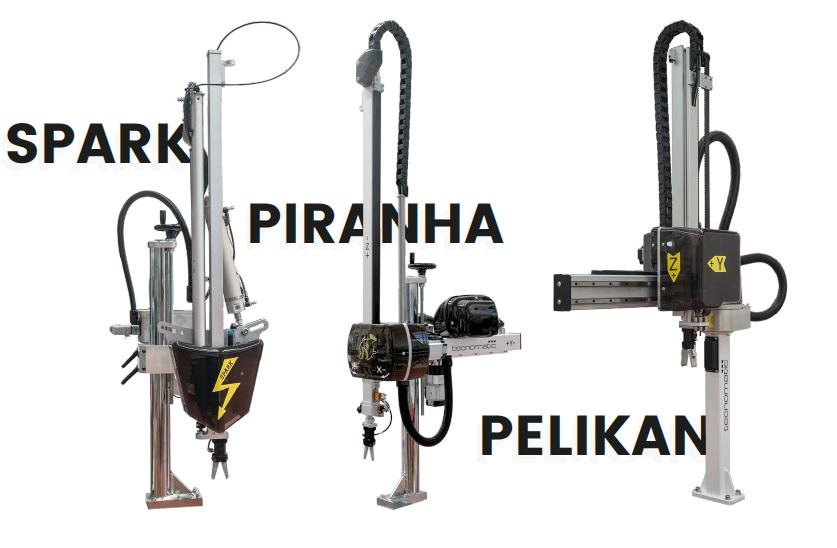

The MICRO CNC robot responds flexibly and economically to most of the requirements for the small injection molding machines.

The Free Guided Programming (FGP) function, which all TecnoMatic robots have, makes it possible to realize extremely flexible work cycles without limits on the complexity or duration of the program; all the different operations are very simple.

OTHER TECHNICAL FUNCTIONS

- Brushless servo motors on the three axes;

- Movements of the axes by precise prismatic guides and skates mounted on bearings;

- Epicyclic type reducers;

- Interpolated axes movement;

- Two vacuum circuits and two gripper circuits as standard;

- Piece presence control by digital vacuum switches;

- Time control signal for switching on the conveyor belt;

- External outputs and inputs freely programmable to connect the robot to another machine.

CONTROLLER SPECIFICATION

- Mobile leather hanger with 7 color touchscreen display;

- Self-study of the positions of the axes by manual movements;

- Execute step-step of the program at reduced speed to verify its accuracy;

- Ability to realize work cycles consisting of any sequence of movements;

- Memorization of the work programs on USB stick.

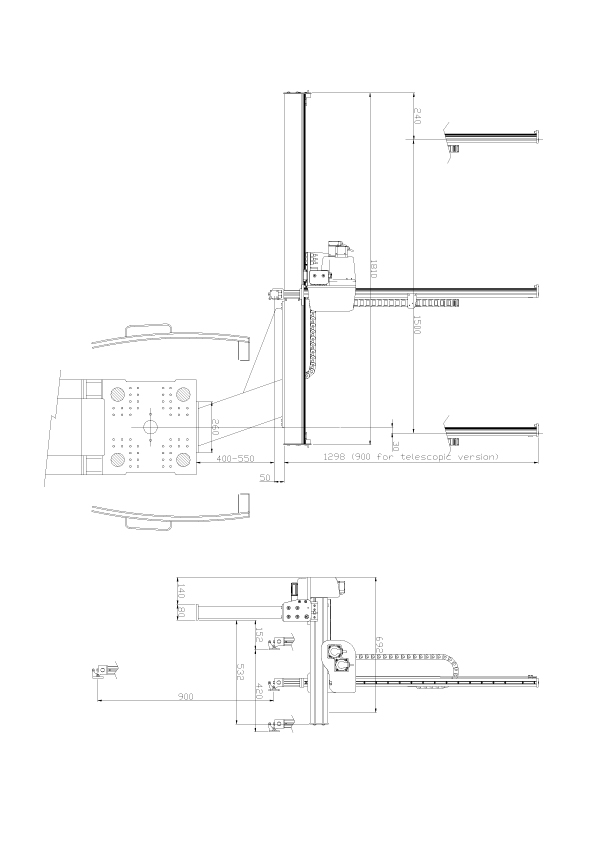

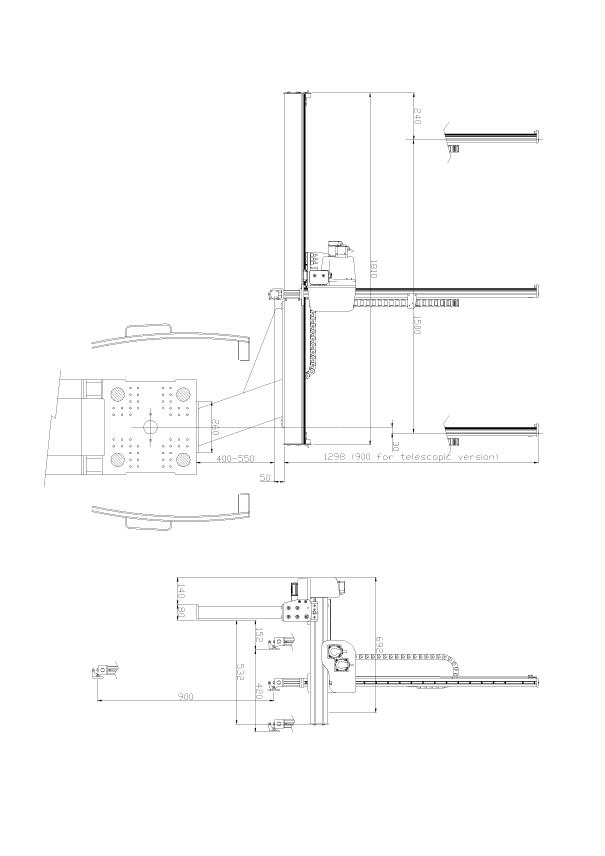

| Fashion model | IMM (tons) | std. Strokes (mm) | min. cycle time |

| Micro CNC | 20-120 | Traverse: 1500 | 5 sec |

| Demoid: 420 | |||

| Vertical: 900 | |||

| Max payload (Kg) | repeatability (mm) | Power supply (V) | |

| 3 | ± 0.1 | 220 AC 1 phase |