The CNC robots in the COMPACT series are the ideal partners to automate standard processes for the injection molding of thermoplastics. By optimizing production techniques in combination with the choice of the best components, an exceptional price-quality ratio can be achieved.

Programming is simple and intuitive and allows to run work cycles without limitations in terms of the complexity and length of the work program.

The standard functions of this series are really extensive:

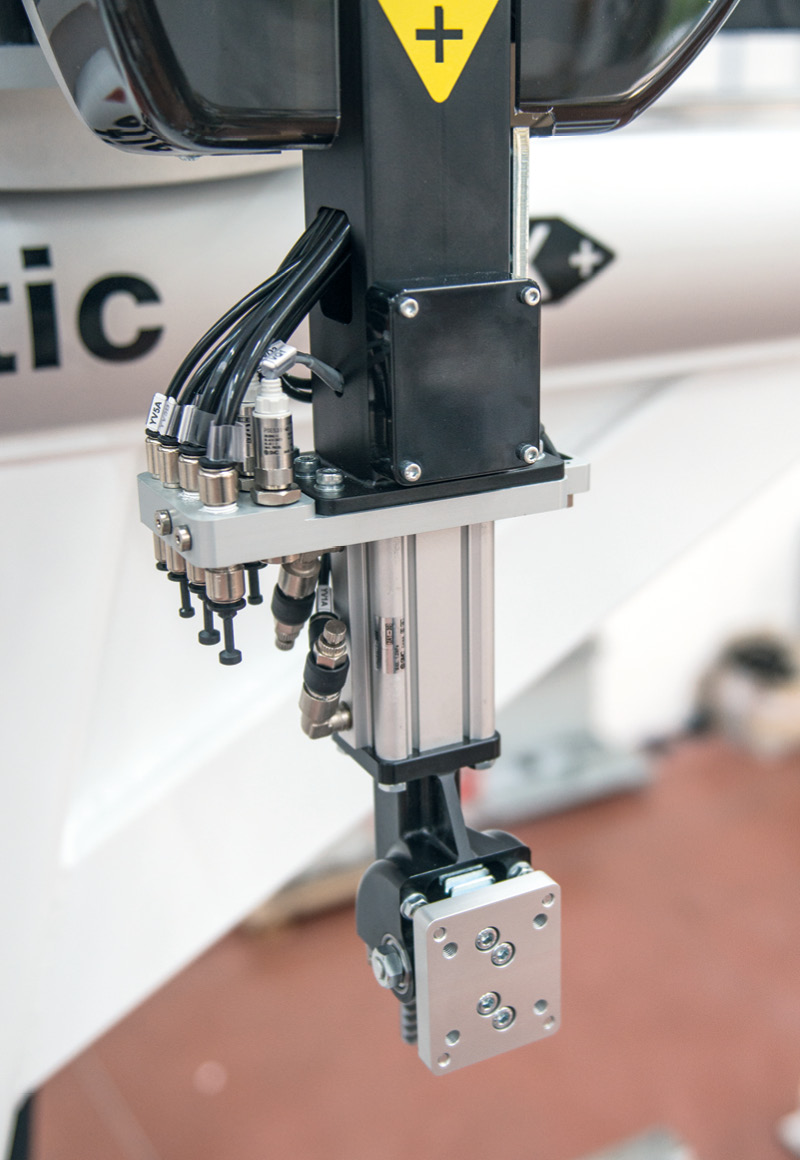

by hand: 2 vacuum circuits, 3 pneumatic auxiliary circuits, 4 freely programmable inputs;

on the electrical panel: 5 inputs and 5 outputs that are freely programmable;

timing control for the conveyor.

OTHER TECHNICAL FUNCTIONS

- Brushless servo motors for all axes;

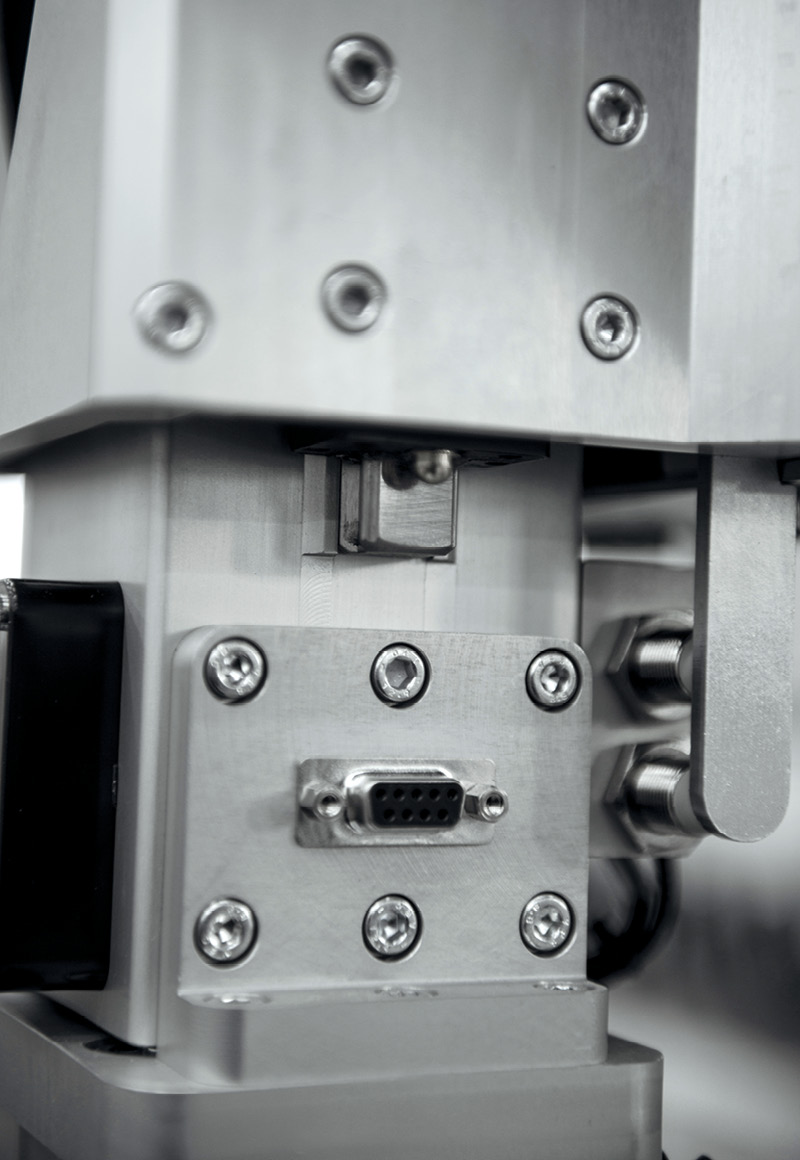

- Axis movement on prismatic rails and recirculating ball skates;

- planetary type speed reducers;

- Movement transfer via a very strong toothed belt;

- CPU with numerical control (CNC);

- External keyboard with large color screen, 10-inch touchscreen;

- Simultaneous movement of the axes via interpolation and interposition of beam;

- Control of the piece clamps via analog vacuum switches with settings on the display.

OPTION

- Hand rotations by servo motors.

PROGRAMMING

- Tutorial of the working positions of the axes;

- Step-by-step execution of the work program at reduced speed so that accuracy can be checked;

- Work programs are stored on a USB stick;

- Numerous palletizing formats ready to use;

- Ability to insert different kinds of logical conditions in the main program (for example to reject defective pieces, insert cardboard interlayers, etc …);

- Ability to cut the sprue using an external cutting station (optional);

- Ability to label the part with an external labeling machine (optional);

- Ability to extract pieces with undercuts;

- Ability to insert metal parts into the mold while withdrawing the finished pieces at the same time;

- Ability to remove the pieces from the solid part of the mold.

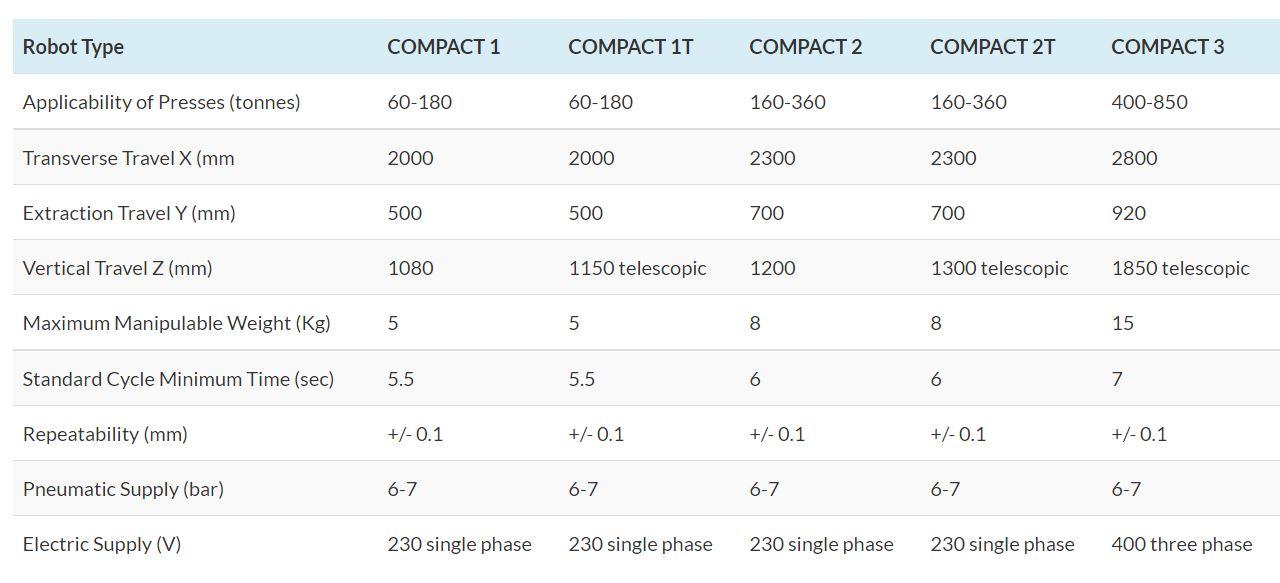

| Robot Type COMPACT | 1 / 1T | 2/2T | 3 |

| Applicability of Presses (tonnes) | 60-180 | 160-360 | 400-850 |

| Transverse Travel X (mm | 2000 | 2300 | 2800 |

| Extraction Travel Y (mm) | 500 | 700 | 920 |

| Vertical Travel Z (mm) | 1080 (1) – 1150 telescopic (1T) |

1200 (2) – 1300 telescopic (2T) |

1850 telescopic |

| Max Manipulable Weight(Kg) | 5 | 8 | 15 |

| Standard Cycle Minimum Time (sec) | 5.5 | 6 | 7 |

| repeatability (mm) | +/- 0.1 | +/- 0.1 | +/- 0.1 |

| Pneumatic Supply (bar) | 6-7 | 6-7 | 6-7 |

| Electric Supply (V) | 230 single phase |

230 single phase |

400 three phase |

- Ideal for automating standard processes for the injection molding of thermoplastics.

- Programming is simple and intuitive