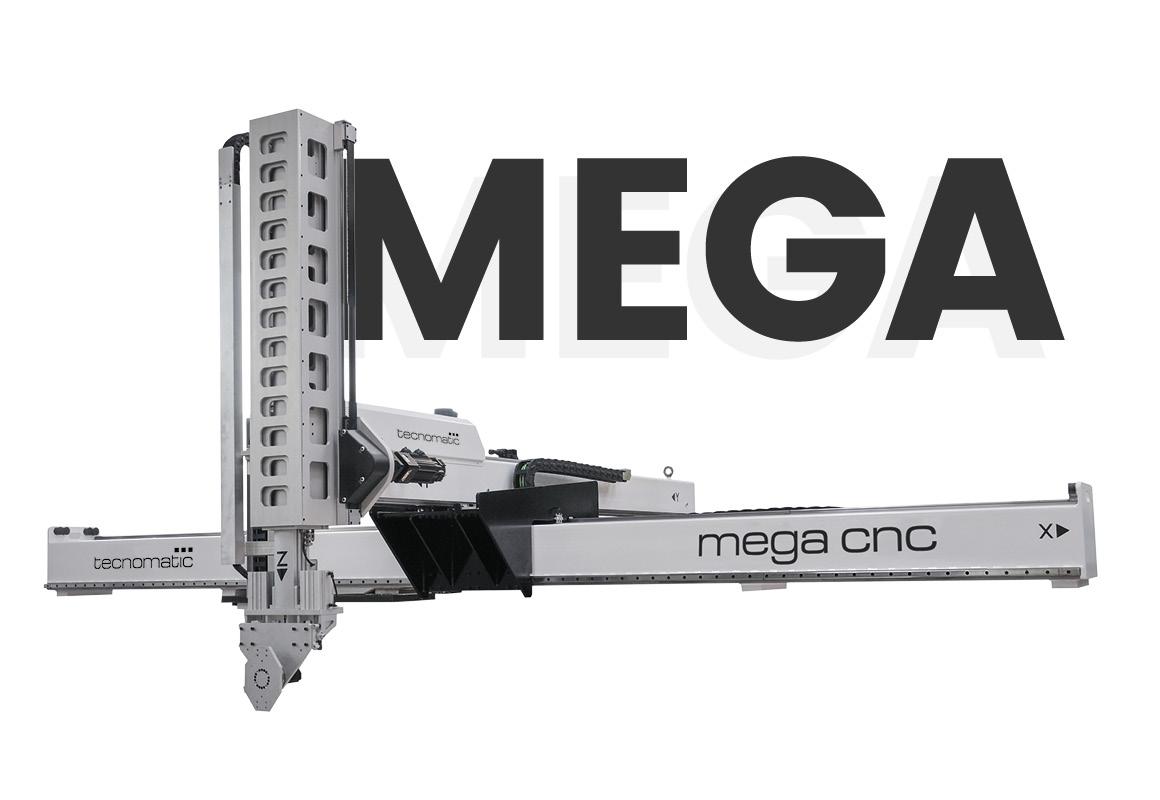

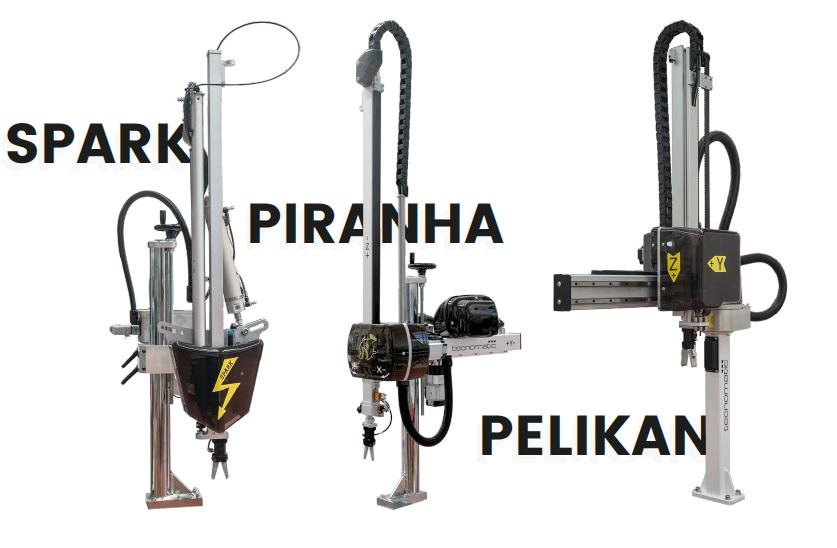

The powerful linear robots of the STEEL series represent the culmination of more than 30 years of activity by TecnoMatic in the automation of plastic injection molding machines.

This series is the result of constant evolution, both in terms of mechanical and electronic components.

The high speed, vibration control and high loading capacity place this series at the highest technological level.

The CPU is equipped with a powerful programming mode (Free Guided Programming – FGP) that makes it easy to program even very complex work cycles.

They are also the most intuitive robots ever and are easy to use even by operators who are not particularly specialized. The load-bearing structure is made of steel to obtain great structural rigidity. The alloy telescopic vertical shaft makes it possible to achieve high speeds and acceleration levels.

The components used are the best available on the market, produced by leading companies in the reference sector.

OTHER TECHNICAL FUNCTIONS

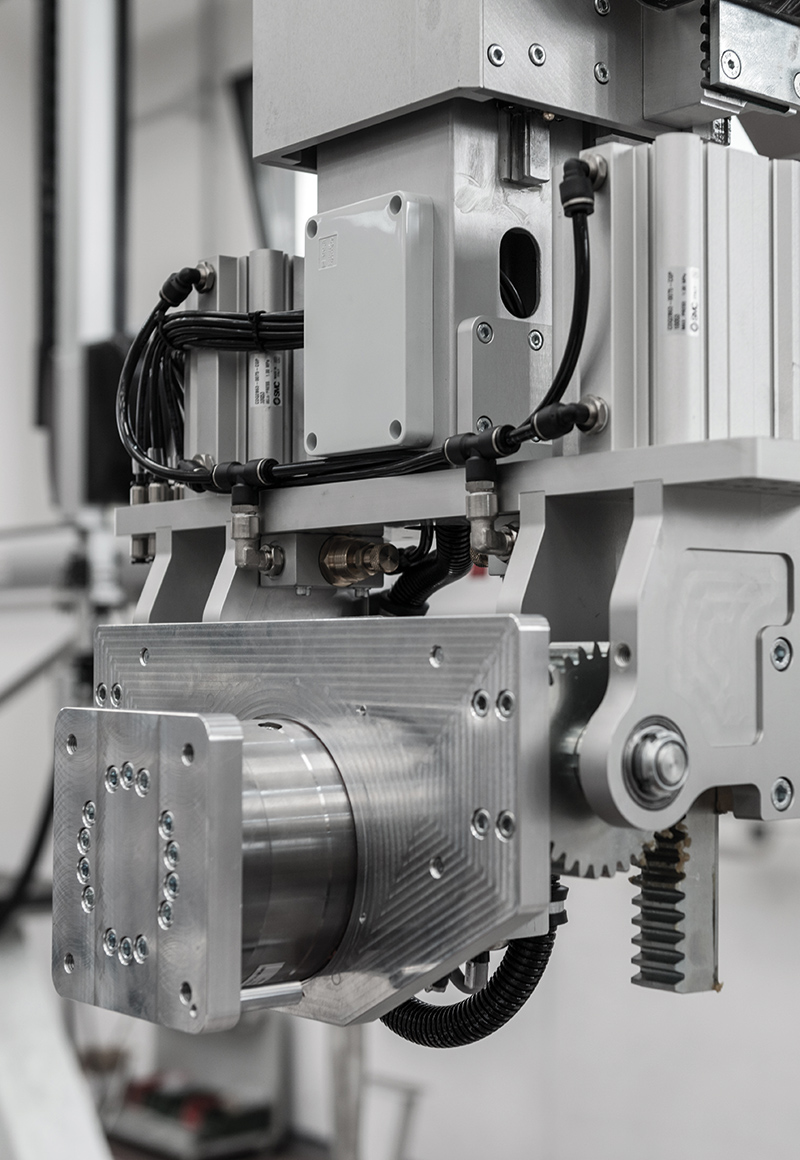

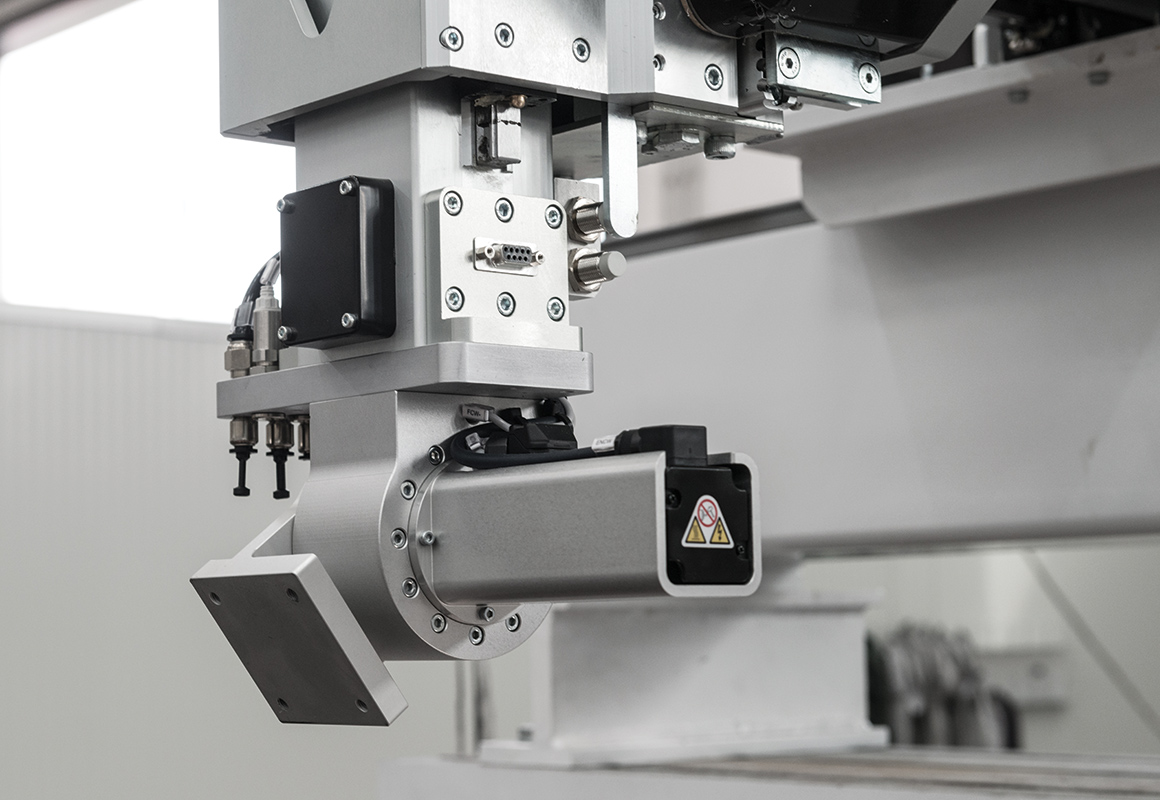

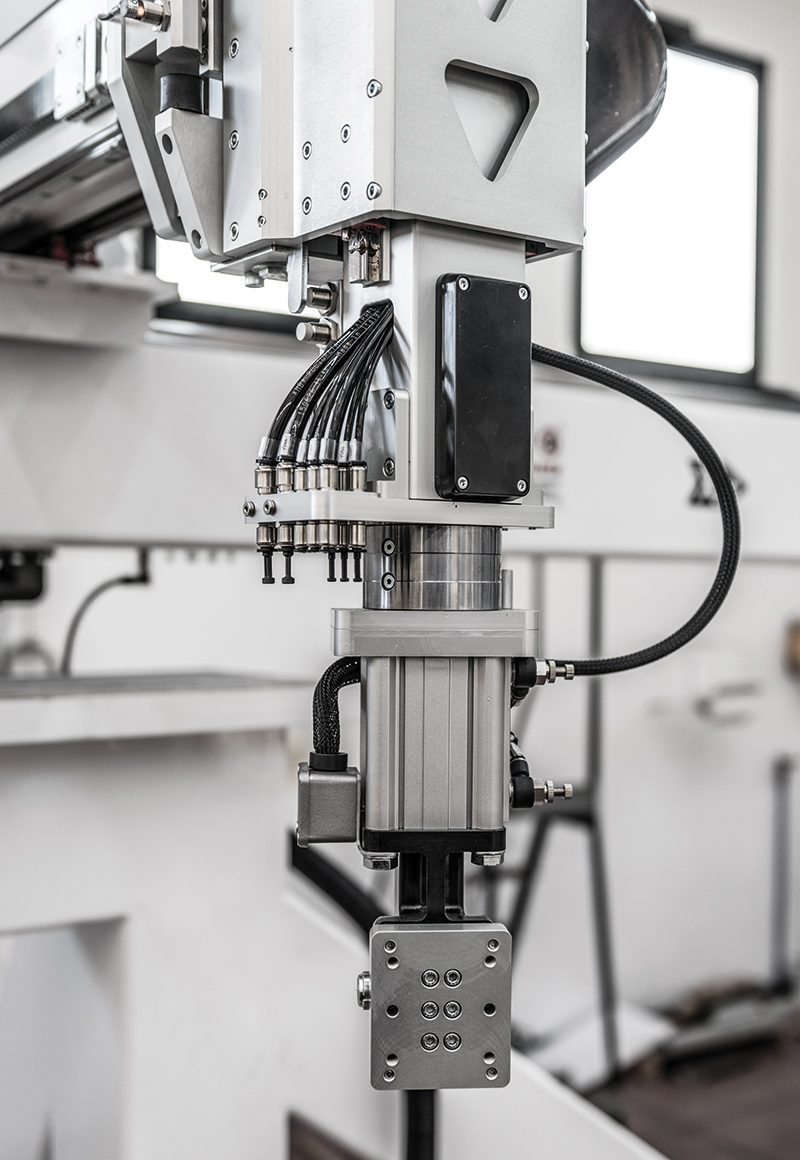

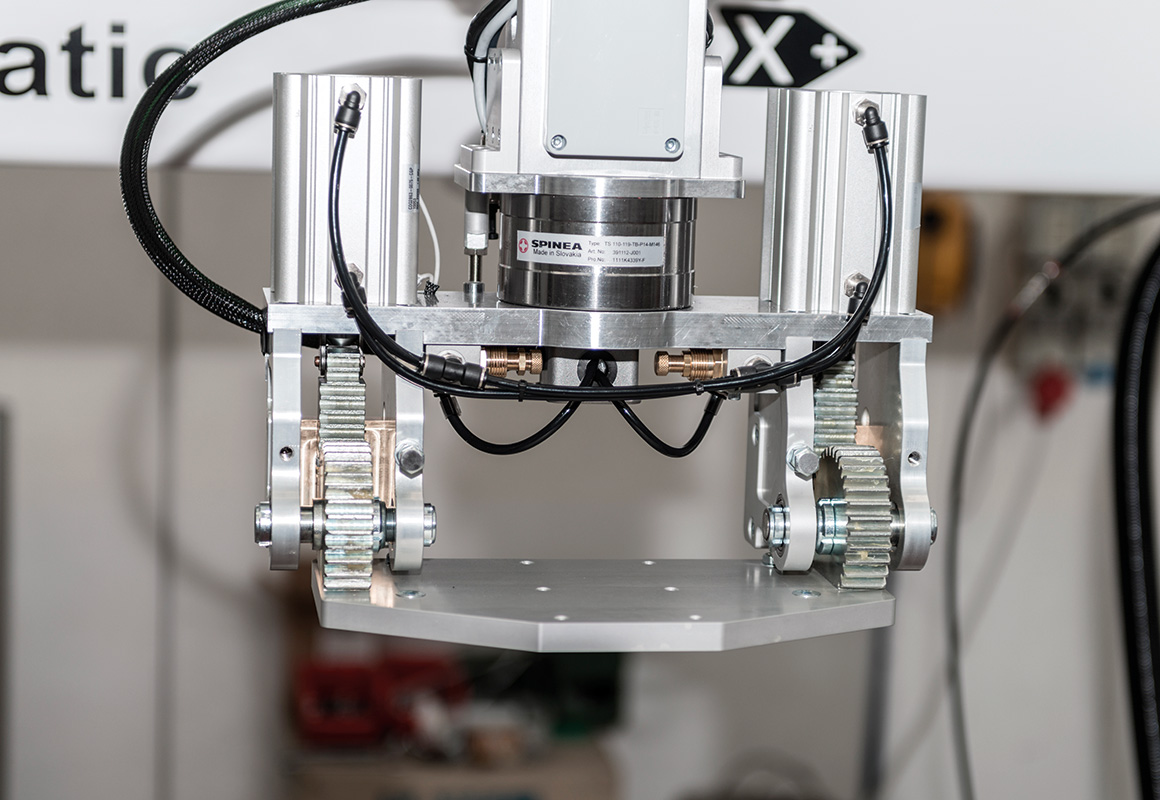

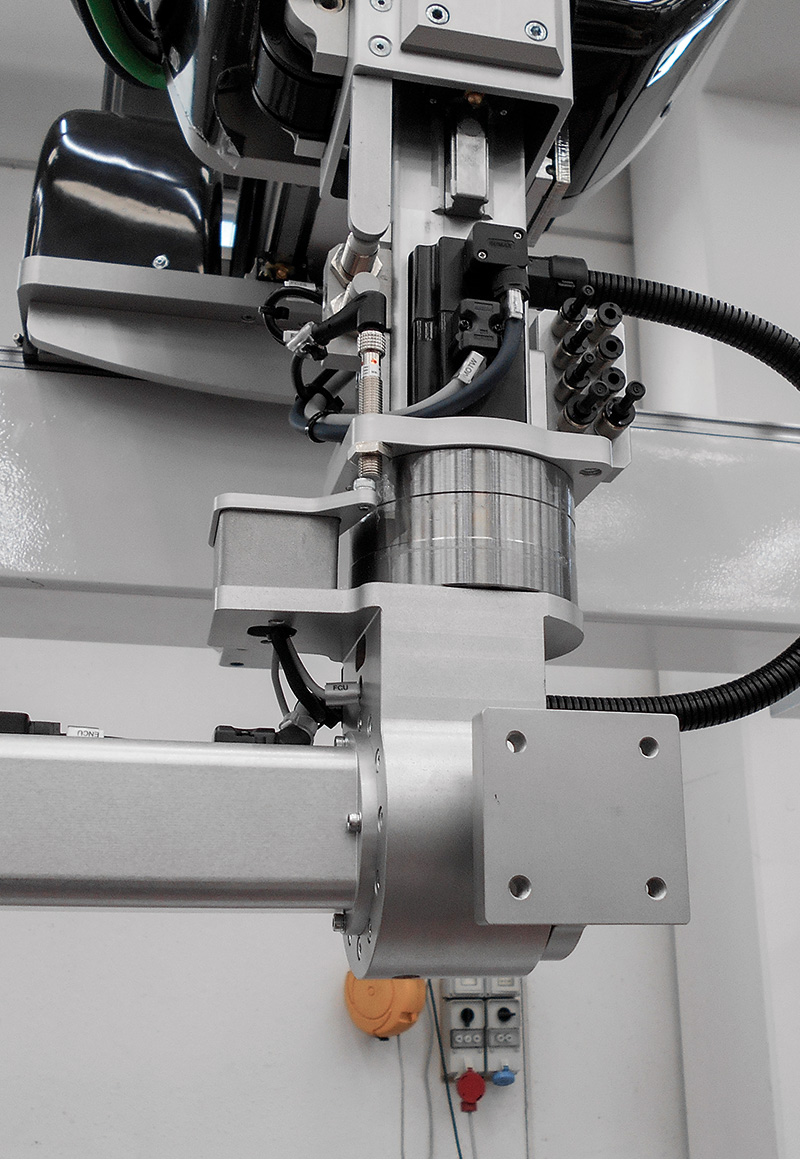

- Powerful brushless servo motors on all axes;

- Telescopic vertical shaft on all models;

- Axis movements on custom prismatic guides and ball bearing guides;

- Epi cyclic speed reducers;

- Axis movements via high-resistance toothed belts;

- Ability to perform movements with torque control;

- Detachable programming keyboard with over 10 touchscreen color displays;

- Interpolation and superposition of the movements of all axes;

- Successive movements performed with connection radius;

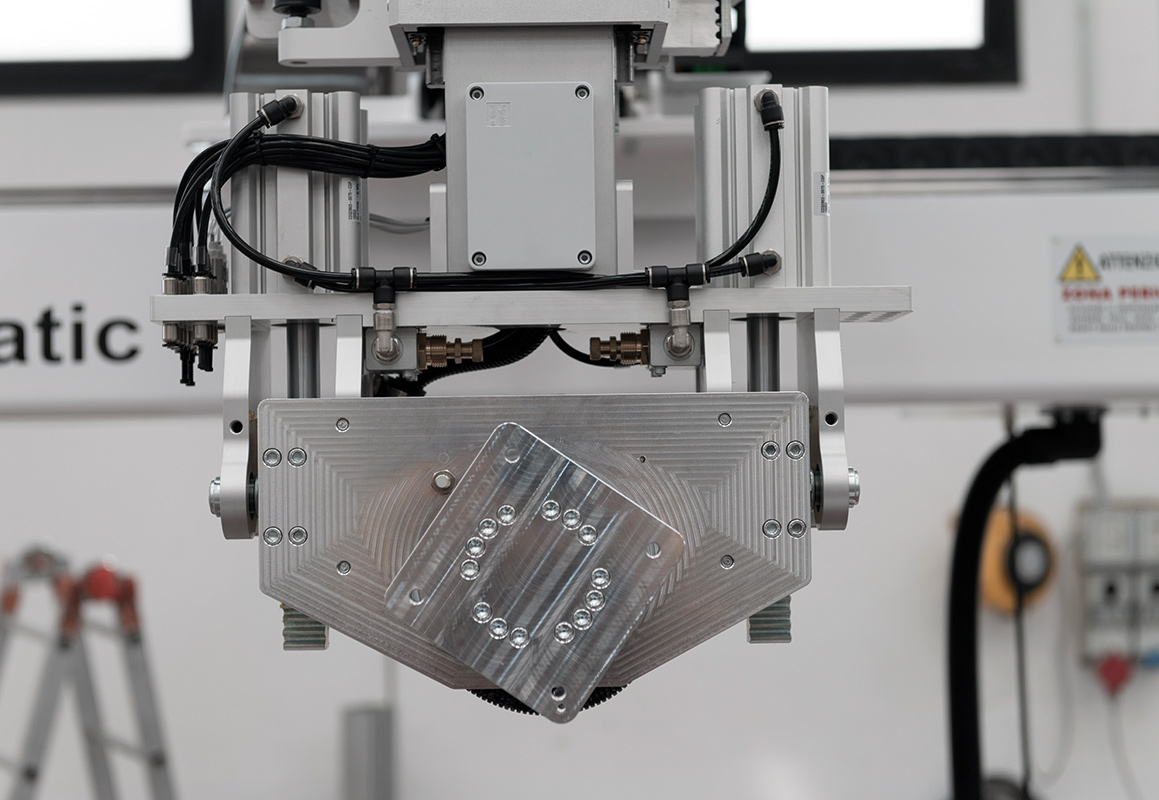

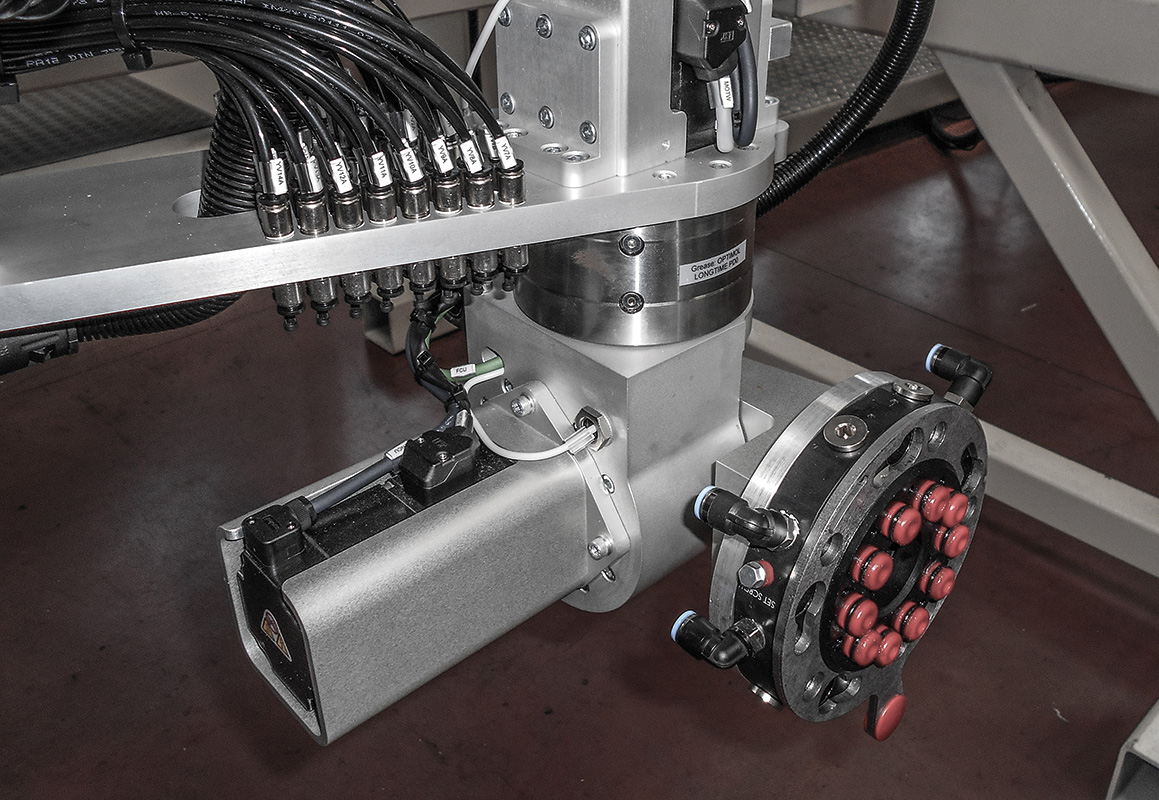

- Standard on the pick-up hand: two analog vacuum circuits, four pneumatic circuits, five digital inputs;

- Checking the presence of the workpiece by means of analog vacuum switches calibrated via the programming keyboard or photocells;

- Timing signal to drive a conveyor belt;

- On the electrical board, five inputs and five outputs that are freely programmable to link the robot with other automations placed downstream of the robot.

PROGRAMMING

- The Free Guided Programming (FGP) allows to create the work program using already written actions located in a specific folder;

- Automatic self-learning of the height of the axles;

- Step / step execution and low speed of the created program to verify the accuracy;

- storage of programs on USB memory;

- Numerous workpiece palletizing and depalletizing schemes, for filling pallets, boxes, etc…;

- Possibility to include in the main program different kinds of sub-programs that are executed when there are suitable conditions (they are used for example to reject defective pieces, insert interlayers, etc …);

- Ability to take out pieces with undercuts;

- Ability to place metal parts in the mold while removing the molding at the same time;

- Ability to remove the piece from the solid part of the mold.

MAIN OPTIONS PROVIDED

- Addition to the take-out hand of additional vacuum circuits;

- Addition to the take-out hand additional pneumatic circuits;

- Addition to the removal hand additional inputs;

- Addition in the electrical panel of additional inputs and outputs;

- Installation of a second pneumatic rotation that can be set to 90° or 180°;

- Possibility to manually install up to three servo rotations that are freely programmable from 0-360°;

- Ability to install a sprue cutting kit;

- Possibility to install a kit for applying self-adhesive labels;

- Adjustment of the axes relative to the standard strokes;

- Possibility to install a 3-piece telescopic vertical axis on the models Extra large CNC and Large CNC (on the models XXL CNC and MEGA CNC this is already standard);

- Wireless remote control for assistance and monitoring.

- High speed, vibration control and high load capacity

- Highest technological level

- Powerful programming mode

- Intuitive robots and easy to use