Die Lifters

Mold handling

Quick, accurate and hassle-free mold exchange or transport

THAT LIFT

Position your heavy molds with minimal force, it is possible with the extensive range of lifters from EAS. EAS die lifters are standard classified into three categories based on the operating principle: spring-loaded, hydraulic or pneumatic.

Application

For lifting, moving, positioning and lowering heavy molds on vertical presses, such as die-cutting machines and vertical injection molding machines.

Function

Those lifters work with roller systems. By rolling, your mold enters or exits the press without any problems and in the correct position. Depending on the weight of your molds, rolling is done via a single ball, via multiple balls or on rollers.

BALLS, ROLLERS AND RODS

Roller systems on balls provide extremely flexible movement. The mold can be moved in any direction and can therefore be positioned flexibly and accurately. A bullet has one point of contact, making the system more suitable for smaller (less heavy) molds.

A roller system is used to move the mold in one direction. The mold can only be moved linearly, ie forwards or backwards.

Thanks to the line contact, roller systems have a greater load capacity than a ball. Roller systems have a greater load capacity.

In order to accurately position heavy molds, roller systems are often combined with pull-pressure systems, such as lead rollers and/or mold change carriages.

The load distribution over several balls (those lifter bars) allows the mold to be moved in any direction without any problems.

MECHANICAL, HYDRAULIC OR PNEUMATIC

Mechanical die lifters are ideal for small and medium-sized molds. These die lifters are spring loaded and do not require a power source. The balls or ball bars are continuously pressed against the mold, even when the mold is clamped. The clamping force of the clamping cylinders is greater than the spring force. When the clamping cylinders are retracted, the spring-loaded balls lift the mold back up so that the mold can be moved.

Heavier molds are lifted by powerful hydraulic cylinders. Hydraulic systems retract when the pressure is turned off.

Pneumatic die lifters guarantee a clean application. Because there is less friction, the mold is easier to move with air pressure systems (manual) than with hydraulic ones. Hydraulic die lifting systems have a greater payload and a greater lifting stroke than pneumatic systems.

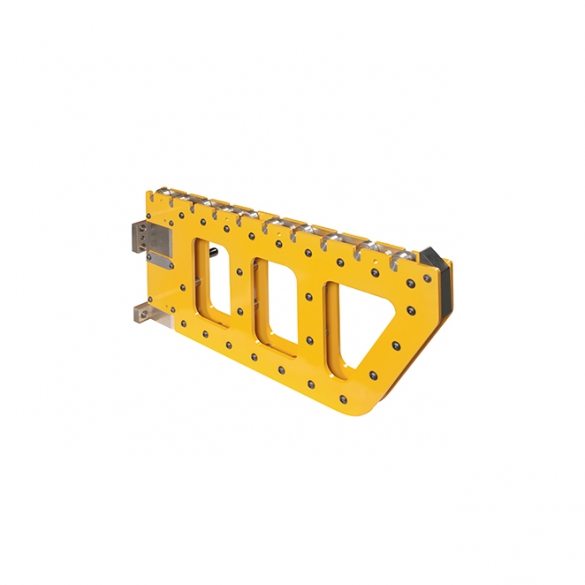

EAS-DIE LIFTER SYSTEMS WITH ROLLERS AND BALL RODS

- SMB – Spring loaded die lifting system with balls

- EMB – Spring loaded die lifting system with balls

- EHB – Hydraulic die lifting system with balls

- EHR – Hydraulic die lifting system with rollers

- DL – Hydraulic die lifting system with rollers (English units of measurement)

- DAB – Pneumatic die lifting system with balls

- DAR – Pneumatic die lifting system with rollers