The SPARK, PIRANHA and PELIKAN pickers are mainly designed for the removal of sprues from the mould : these pickers allow the automatic separation of the sprues from the parts and immediate recycling of the material. There is also a guarantee that the sprue will not remain in the mould, creating a risk of mold damage.

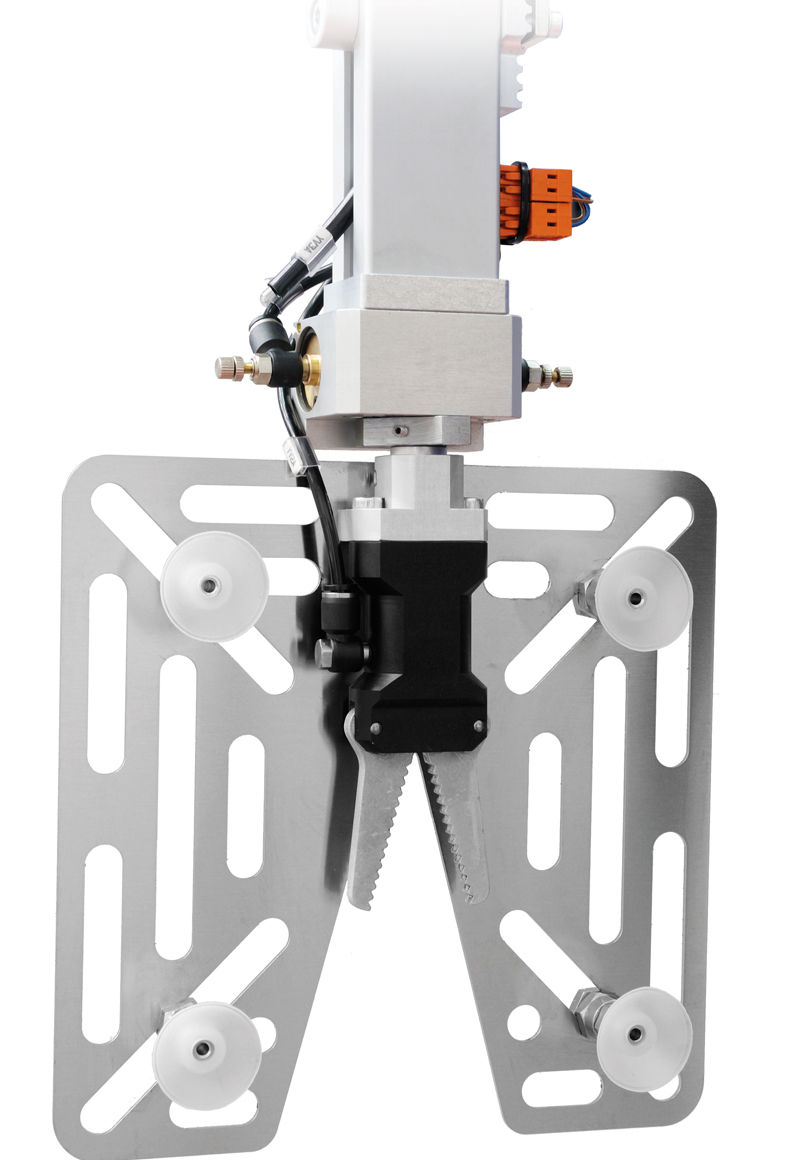

Suction cups can also be used in the case of the PIRANHA and PELIKAN models to remove the products from the mould.

The rapid movement speed in the mold means that the time the mold is open is limited, especially in models with servo motors (PIRANHA and PELIKAN).

Specific features of the different models

SPARK

- All movements are pneumatic to keep costs low.

- The vacuum kit is optional and cannot be used at the same time as the sprue grab.

- Gripper rotation is optional.

- The (6) programs are fixed.

- The sprue is released outside the doors of the injection molding machine, possibly directly into the grinder

PIRANHAI

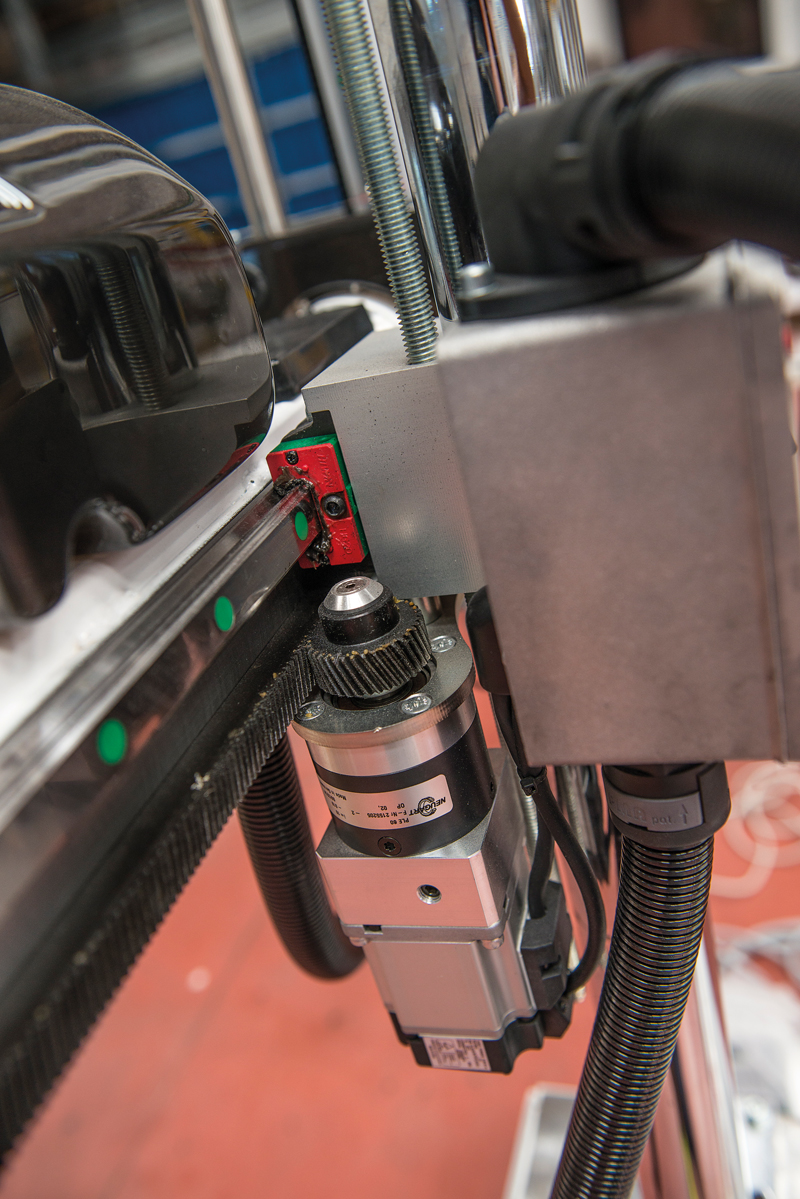

- All movements are made via brushless servo motors.

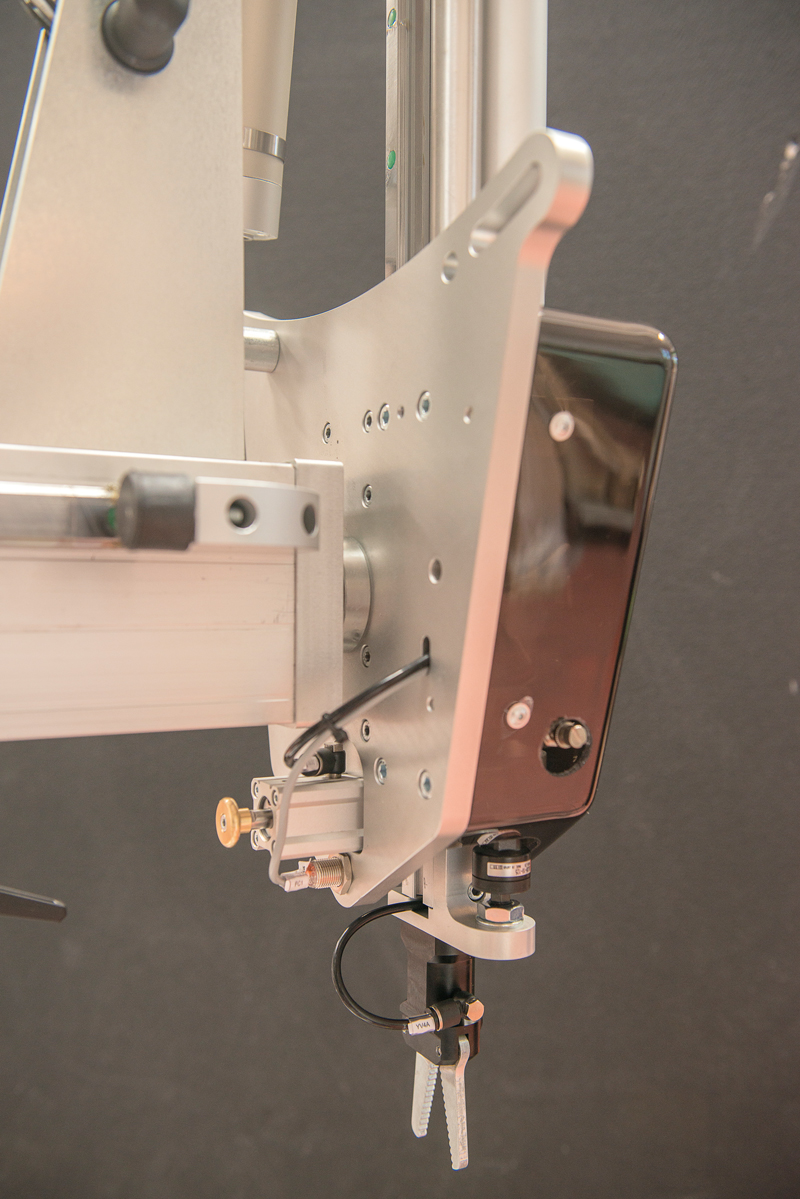

- The vacuum kit is standard and can be used at the same time as the sprue grab.

- Gripper rotation is standard.

- Programming is included.

- The sprue is released outside the doors of the injection molding machine, possibly directly into the mill.

PELICAN

- All movements are made via brushless servo motors.

- It is most suitable for small injection molding machines.

- The vacuum kit is standard and can be used at the same time as the sprue grapple.

- Gripper rotation is standard.

- Programming is included.

- Possibility as an option for telescopic vertical axis.

- The sprue branches are released within the doors of the injection molding machine, possibly directly into the grinding mill

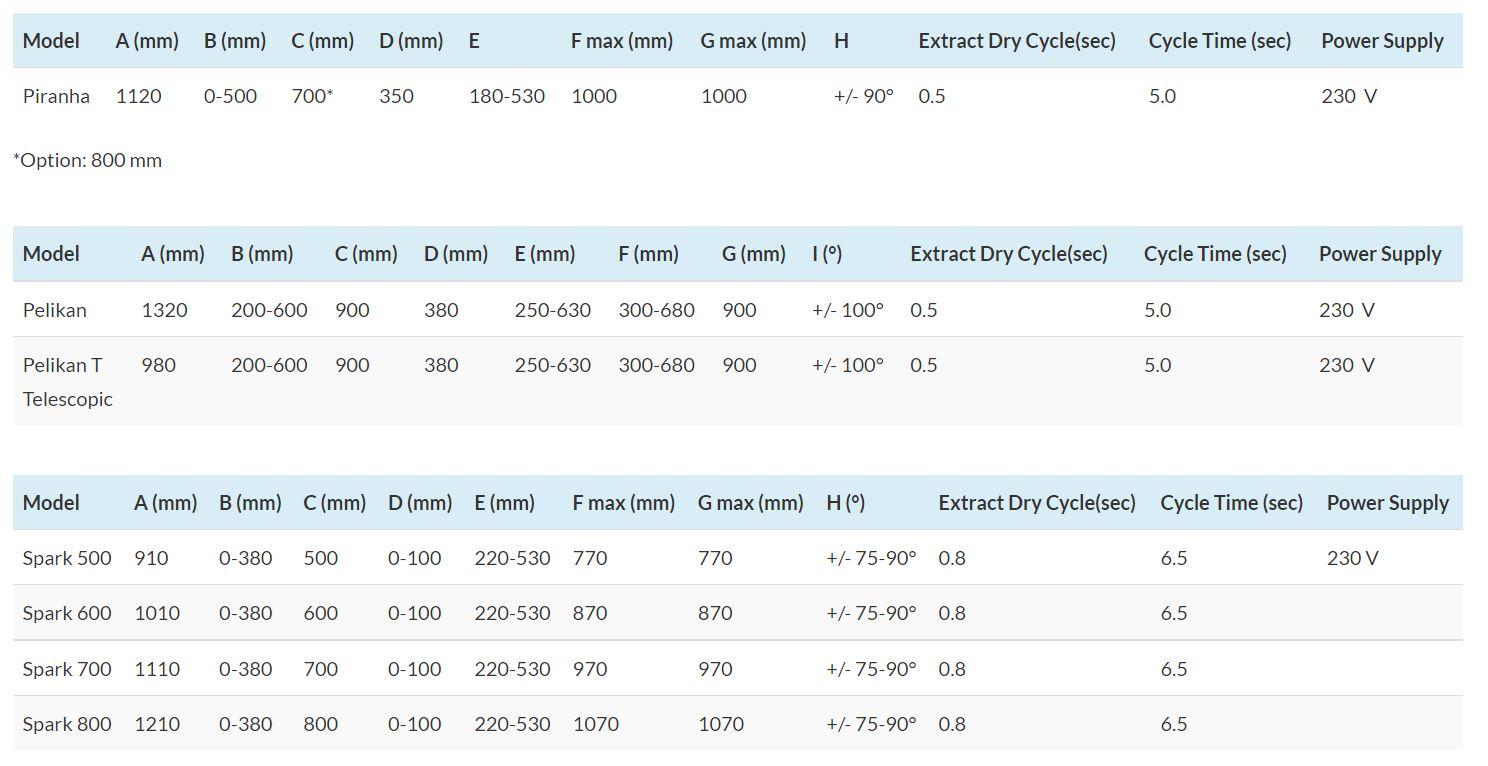

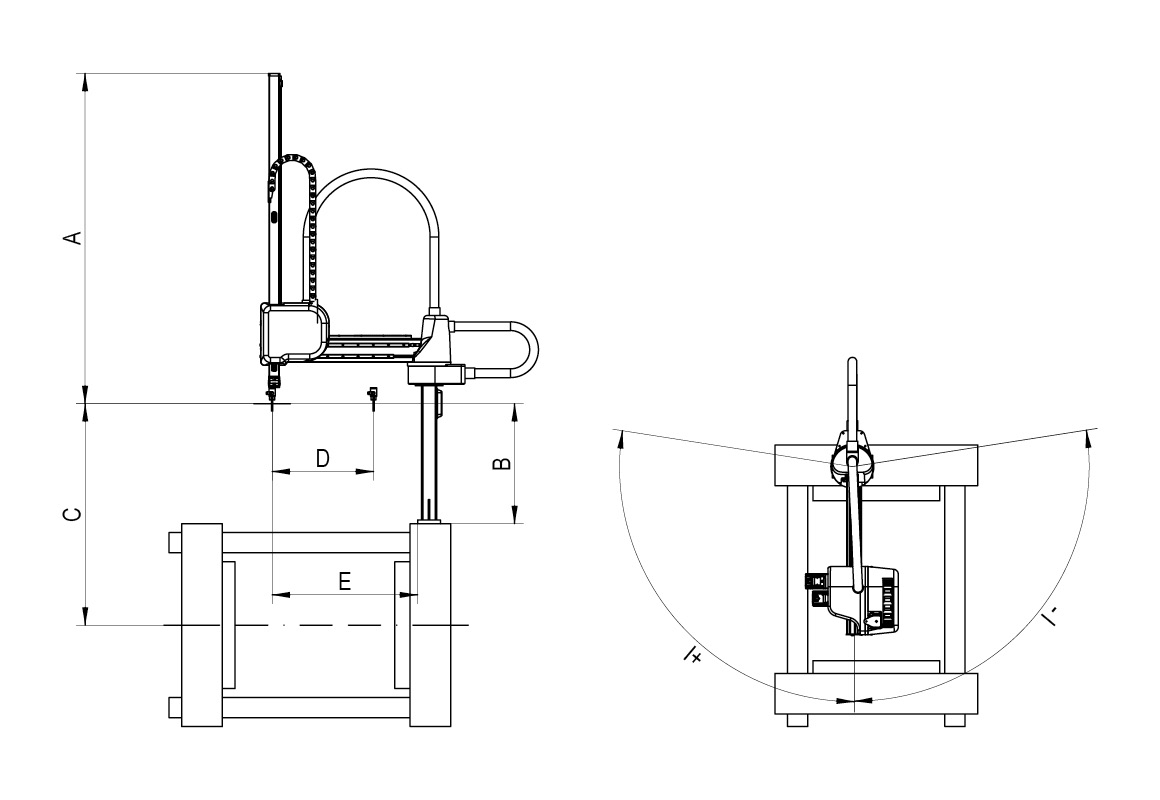

Technical features of the PIRANHA and PELIKAN models

- Axis movements via three brushless servo motors;

- Very fast input and output movements from the mold;

- Low energy consumption;

- Very Simple Guided Programming (FGP);

- Remote control keyboard with 7 color touchscreen display;

- Work programs can be saved on a USB stick;

- Option of interpolation and superposition of movements;

- Option to remove both sprue and products simultaneously;

- Output for conveyor command;

- Inputs and outputs to communicate with the peripherals.

Technical features common to all models

- Very solid mechanical structure;

- Movements on prismatic guides with recirculating ball bearings;

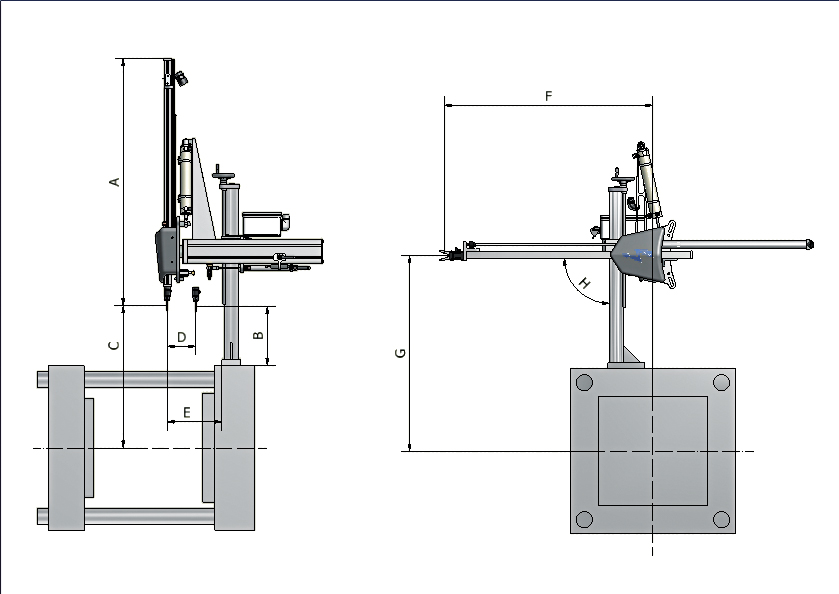

- Mounted above the fixed plate of the injection molding machine;

- Very easy to use;

- Option to release sprue on both operator side and opposite side;

- Option to work with molds with a third plate;

- Lateral rotation of the manipulator to make it easier to assemble the mold in the injection molding machine.

- Sprouts are automatically separated from the parts

- Sprouts can be recycled immediately

- Fast movement speed = Die limited open