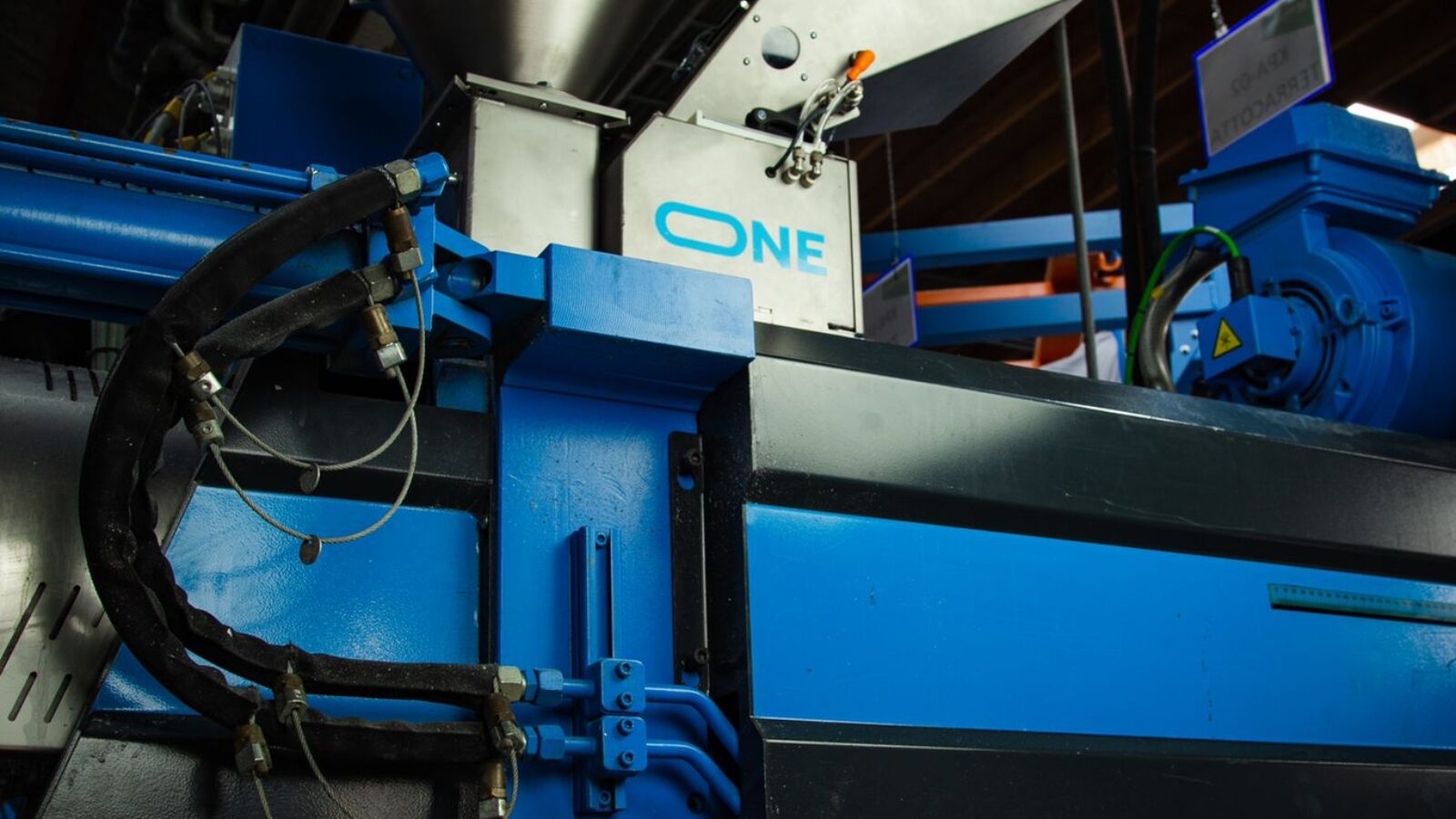

Product in the picture: One by Ferlin

Our sector is moving fast forward thanks to innovation. That’s why we want to place products in the picture that match the needs of today’s market. The product we want to talk about is the patented gravimetric dosing unit One by Ferlin.

The One by Ferlin ensures that the right amount of masterbatch is added to the plastics. Ferlin uses a belt instead of a screw to do this more precisely. This makes the dosing unit more stable & precise than today’s market standards.

Why is a high-quality gravimetric dosing unit critical?

The percentage of masterbatch is only 2 or 3% of the total volume. This requires an extremely precise machine to ensure that the exact amount of colour is added to the plastics. This is why we opted for a gravimetric dosing unit instead of a volumetric dosing unit.

Everyone is familiar with the centuries-old saying ‘to measure is to know.’ By weighting the masterbatch, you know precisely how much granulates you are dosing & we don’t need to consider the masterbatch’s density. This makes the One by Ferlin a more reliable asset in your production process.

In short, thanks to One by Ferlin, we can guarantee a continuous output with the same percentage of masterbatch.

Technical benefits of the One by Ferlin

To give you a better understanding of the benefits, we list them for you.

- It features a simple cleaning system.

- A smaller loadcell to weigh more precisely.

- One by Ferlin is equipped with a belt to avoid overusing additives or masterbatch.

- Touch screen control panel with a friendly user interface.

- No calibration is required compared to a volumetric dosing unit..

- Save masterbatch by weighting.

Discover the benefits for yourself

To introduce you to the One by Ferlin; we would be glad to invite you for a test with this innovative patented gravimetric dosing unit. Contact us via this link for an appointment.

Technical specifications

Below, you will find an overview of the technical specifications of the One by Ferlin. Additionally, we have attached a document with an overview of the dimension of the machine to this article.

- Loadcell of 3kg

- Capacity hopper of 7kg

- Total weight including control panel is 15kg

- Compressed air of 6 bar

- Power supply with a power of 240v 50/60Hz

- Energy consumption of 45w

- Dosing capacity of maximum 30kg/h

More news

PRS Europe 2024

- JUNE 2024PRS EUROPE: June 19 & 20, 2024! The exhibition in the field of plastic recycling!

Fakuma 2023 ⏩

- OCTOBER 2023FAKUMA: from Oct. 17 to 21, 2023! The 28th international trade fair for plastics processing!

Plastics fair 2023! 👋

- SEPTEMBER 2023Will we also meet you at the Plastics Fair on September 20 & 21, 2023? Visit us at booth 264!