Units of the ID-BD and CD-TD series only work with compressed air and complete the product range of dryers.

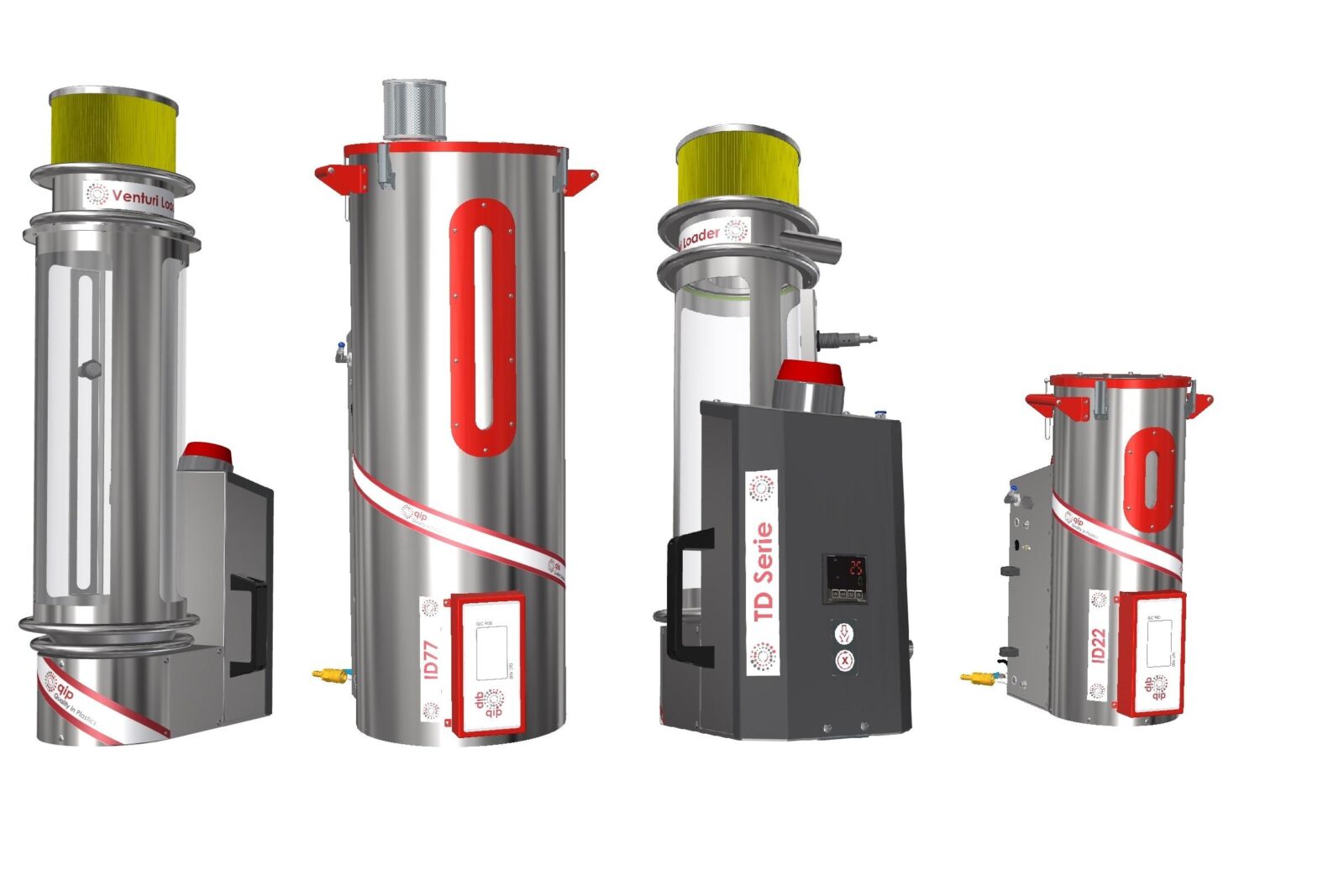

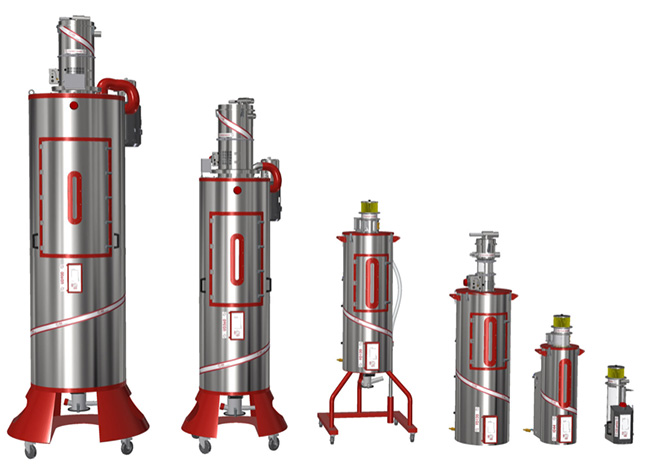

CD: Compact Dryer (2.5 – 11L)

TD: Tiny Dryer (2.5 – 11L)

BD: Basic Dryer (11 – 170L)

ID: Intelligent Dryer (22 – 170L)

They are very popular for small material throughputs due to their unique stability of the drying process and the possibility to mount them directly on the production machine.

Only small amounts of compressed air are required.

The compressed air dryers from QIP GmbH represent the next generation of plastic granulate dryers with compressed air.

In addition to the great advantage that no desiccant is needed to generate dry air for the drying process,

This dryer offers a full round drying funnel made of high-quality stainless steel and a heat-resistant, transparent borosilicate glass tube, without air inlet hoses.

This minimizes the cleaning effort when changing materials and opens up further possibilities for processing the material.

The heated air is guided along the outer perimeter into the drying funnel at the bottom, ensuring an efficient and constant heating process.

A very compact design and the possibility to install the unit directly on the production machine make the dryers an excellent and preferred system for drying small material flows.

If desired, the system can also be mounted on a wheeled frame for more flexibility.

The compressed air dryer is ideal for continuous drying of plastics. It combines the advantages of the warm air dryer with those of the dry air dryer, without its drawbacks.

The compressed air dryer preheats the material with warm air, and then uses a small amount of compressed air to remove the moisture from the material. The compressed air is decompressed before being heated and fed to the bottom of the drying funnel. The standard quality of compressed air, with a dew point of 5°C or lower at a pressure of 7 bar or more, is ideally suited for this process.

The central air compressor in the production hall supplies air to various dryers; as a result, less floor space is used in the production hall, and maintenance costs are limited. The energy consumption of the compressed air dryer is much lower than that of a dry air dryer. In certain cases, such as blow molding, energy consumption can be reduced to almost ZERO.

The exhaust air from the process is used for drying, and the heat is recovered from the air compressor.

We would like to inform you that FarragTech GmbH has been incorporated into the Wittmann group.

The group has decided to continue working with their local partners, which means that AJ Solutions can no longer sell these dryers.

It is very important to us that our customers who have purchased Farragtech dryers from us since 2006 receive full warranties on their units, and that we continue to guarantee all parts and service.

That is why we decided to do business with QIP (Quality in Plastics) , this company was started a few years ago by EX technical specialists from Farragtech. The QIP dryers use 95% identical parts than Farragtech. These QIP specialists, with their more than 20 years of experience in the field of material drying and material handling, have further developed and improved the dryers. Due to some major changes in design, the QIP dryers have taken an even big step towards greater energy efficiency.

We have compact intelligent dryers in different versions CD, ID, FD, UD and HD with a hopper capacity from 1.5 liters to 3700 liters.

Compressed air and therefore energy savings of up to 80%! Ask about our interesting introduction proposal.

Benefit from our know-how to reduce your CO2 emissions, we guarantee you absolute process security in your reliable production environment.

Various QIP dryers are in stock here. You can test these and experience the quality of drying yourself.

We look forward to a future of unsurpassed quality along with our commitment.

- Without desiccant

- 3 year full warranty on parts and workmanship

- Maintenance-free

- Consistent drying performance over the entire life

- Low operating costs

- Space-saving, optimized design for direct mounting on the extruder

- Drying Funnel of Heat Resistant Transparent Borosilicate Glass Tube

- High Quality Stainless Steel Metal Parts

- Easy to install and start up

- Intuitive and self-explanatory operation thanks to a colored touchscreen

- Easy to clean