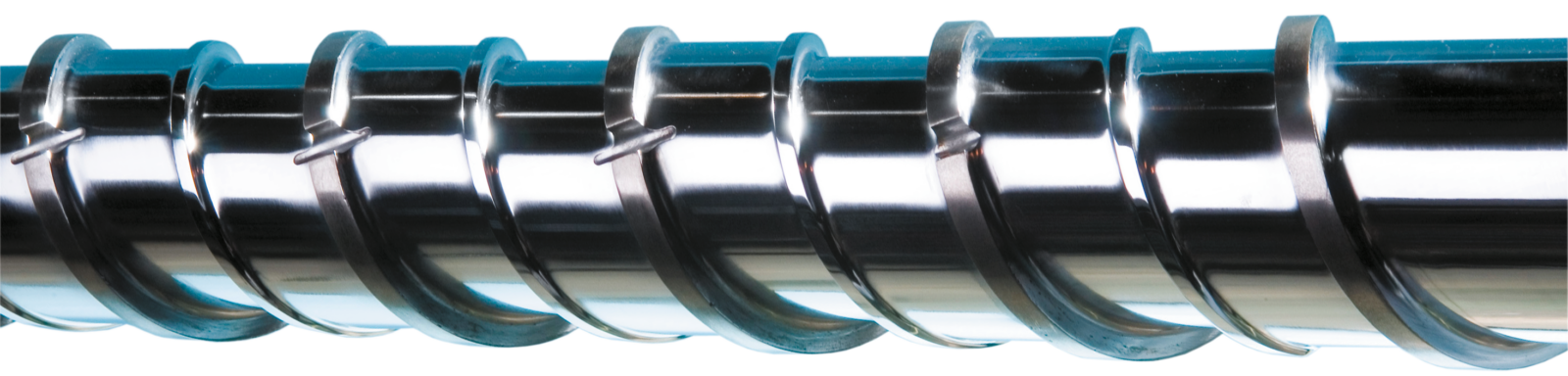

The Xaloy Fusion™ II screw delivers enhanced chaotic mixing while retaining the productivity benefits of faster plasticizing and lower melt temperature provided by the original Xaloy Fusion™ screw. Like the original Xaloy Fusion™ screw, the Xaloy Fusion™ II screw has two barrier zones.

Features

- Two barrier zones – the first melts and meters the material forward to a homogenizing transition zone. This zone is followed by a second barrier zone with an undulating root profile providing intensive, chaotic mixing

- The primary flights in the second barrier zone have grooves, which allows materials in adjacent melt channels to mix together, enhancing the intensive, chaotic mixing action produced by the screw’s undulating root profile

Applications

- Polyolefin high output, low melt temperature processes

- ABS high output processes

- Improved product quality

- Lower melt temperature

- Lower drive motor load

- Improved dispersion of color and additives in the melt and enhanced melt homogeneity through grooved flight design

- Increased plasticizing rate