Design of NEUE HERBOLD Screw Shredders

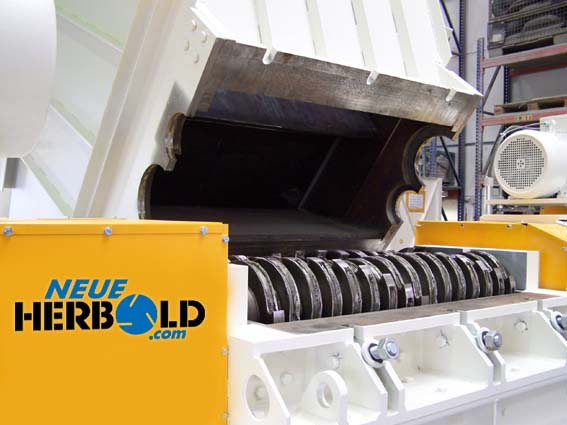

The NEUE HERBOLD Screw Shredder plants are equipped with pairs of similarly helicaly srew shafts.

The breaking shafts are stored in a welded trough-shaped housing. For the separation of sand and soil, the housing can be equipped with a sieve bottom.

The breaking of the feeding material works via shear forces both between the screw shafts and the counter teeth in the housing. The slide shafts are equipped with helical screws, this ensures the horizontally transport to the discharge chute. The inlet to the discharge chute can be narrowed to determine the size and amount of the ejected material.

Applications of NEUE HERBOLD Screw Shredders

The SB shredder plants are used both for the pre-crushing of bulky materials as well as for the breaking of squeezed bale waste. In subsequent process steps this system level allows the removal of foreign bodies.

Large-volume, bulky and also metal-containing materials are suitable for the use of a screw shredder.

Whether porous concrete blocks, lime bricks or wooden pallets, the NEUE HERBOLD Screw Shredder are designed for very high throughputs. By the stable welded steel construction, the machines of the SB series are extremely durable and hold extraordinary loads.

Some examples of the use of the Screw Shredder Plants:

- size reduction of voluminous materials

- size reduction of wooden pallets

- size reduction of cable drums

- size reduction of sheets of insulation

- size reduction of porous building blocks

Technical overview / Performance data

| Type | Feed opening ca. (mm) | Number of shafts | Drive (kw) | Weight (kg) |

| Bale Breaker / Screw Shredder type SB 560/2 | 1600 X 1600 | 2 | 2 X 15 | 6000 |

| Bale Breaker / Screw Shredder type SB 560/4 | 1600 X 2800 | 4 | 4 X 15 | 10000 |

Advantages of NEUE HERBOLD screw shredders

- flexibility in application range

- heavy duty design

- energy-saving size reduction

- low noise level

- extremely high through put rates

- reduced down times