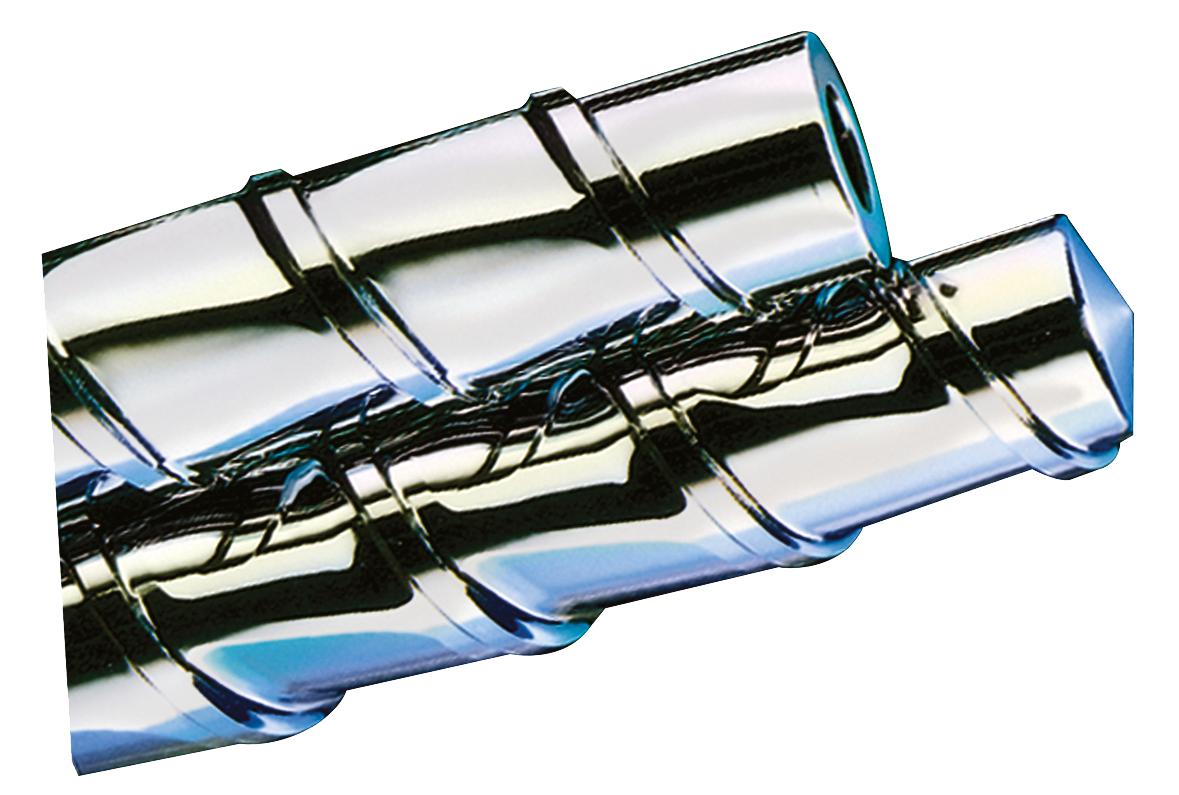

The Xaloy V-Mixer™ screw with its proprietary “pump-through” mixing design generates localized high and low shear areas with low mixer pressure drop. Its unique geometry generates mixing forces in two directions. A squeezing action forces the melt stream towards the barrel wall (up and down) and between the flights (side to side) concurrently. The adjustable channel depth varies the levels of dispersive versus distributive mixing.

Features

- “Pump-through” design gives higher throughput than other dispersive mixers

- Suitable for processing a variety of materials

- Less back pressure required

Applications

- Reduced shear, dispersive mixing requirements

- Enhanced throughput with pump-through screw design

- Increased flexibility through quick color changeability

- No marbling or streaking due to excellent mixing action

- Reduced cost through significantly lower scrap rates

- Excellent part quality and surface finish through controlled screw geometry

- Comparatively lower melt temperatures

- Faster color changeability