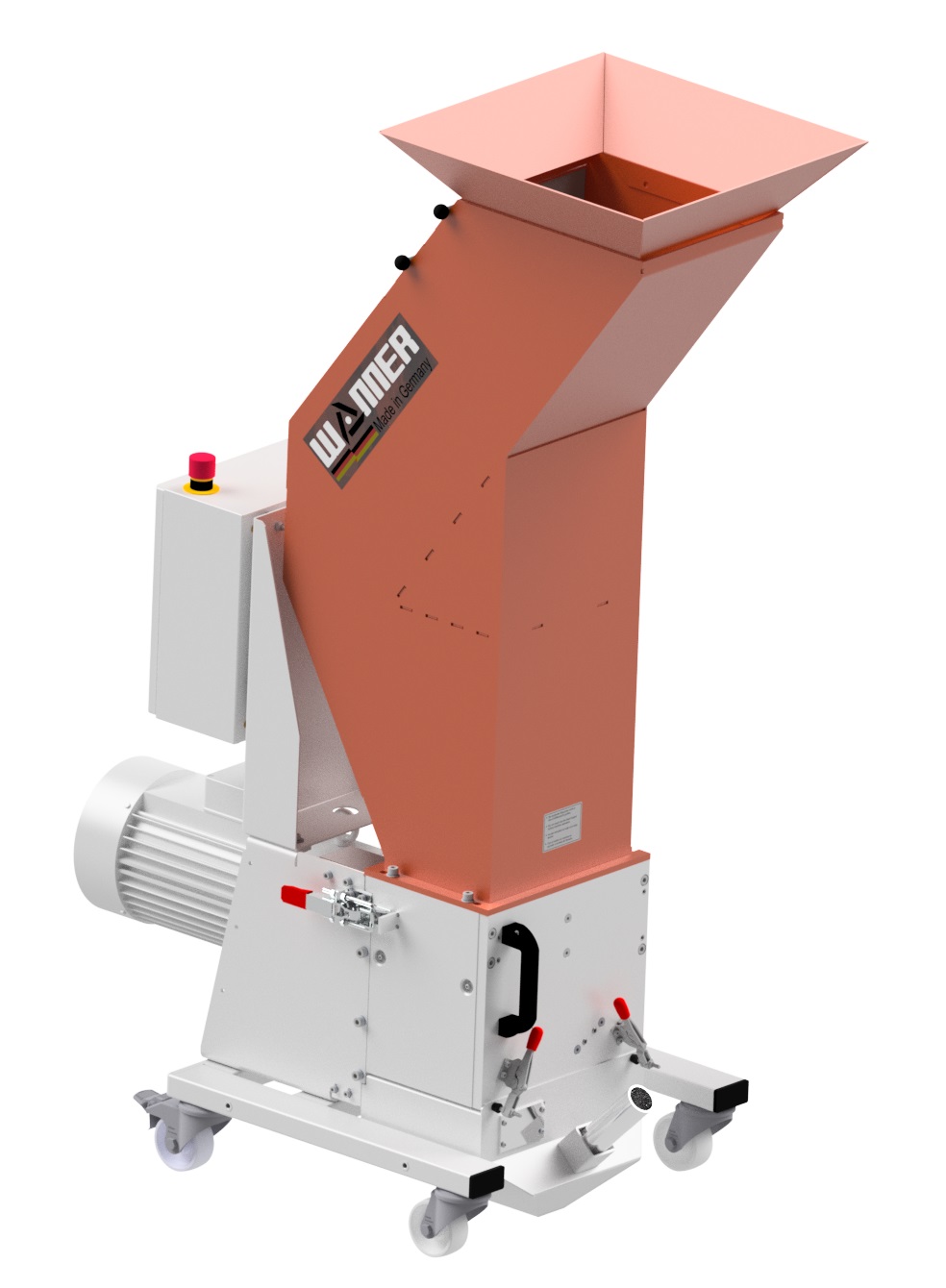

The range of universal side mills, specially designed for injection molding and blow molding applications, built according to a proven concept.

Thanks to the optimum cutting geometry, all common plastics can be processed into high-quality and dust-free regrind. It does not matter whether the plastic to be ground is soft rubber-like TPE or highly filled, abrasive technical material.

Each device has a modular construction, so that special constructions that are adapted to your requirements can be realized quickly and cheaply.

The grinders of the C-series are already equipped with extra hardened, wear-resistant components in the basic version. For these and other reasons, they are ideal all-round machines for any plastics processing company that processes a wide range of different materials. The grinding chamber can be opened quickly and easily, is freely accessible from three sides and can be easily cleaned. This means that frequent material changes are no problem at all. The massive construction of the grinding chamber (from vibration-damping castings) and the double-walled feed shaft ensure that the grinding mill is relatively quiet, even when grinding hard or brittle material.

Specifications Wanner grinding mill C17.31f

- Rotor blades: 12 pieces

- Stator blades: 2 piece

- Motor power: 4 kW

- Screen 5 mm

- With Robot Shaft

- Grinding chamber 170 x 320 mm²

- modular building block system allows easy adaptation to any specific application

- only small footprint required due to compact design

- robust motor and gear unit for a long service life

- Significantly lower noise level due to oblique cutting action and reduction of structure noise through optimized cutting chamber design.

- simplicity of use and easy cleaning saves downtime and money

- Improved pull-in rotor action for bulky parts and clumsy sprues.

- hardened components in the cutting chamber that reduce wear from abrasive materials

- high-quality regrind with low dust content due to optimized rotor design. The rotating side disc in the

- sidewall of the cutting chamber reduces friction and thus prevents heating and eventual degradation of the regrind

- knives easy to re-sharpen without special equipment

- Intrinsically Safe and Silent Feed Funnels

- variety of controls, from simple security control to intelligent system controller with potential-free contacts and alarm system.

- excellent price-performance ratio

Want to check out and test this product? Or receive a quote today?

"*" indicates required fields