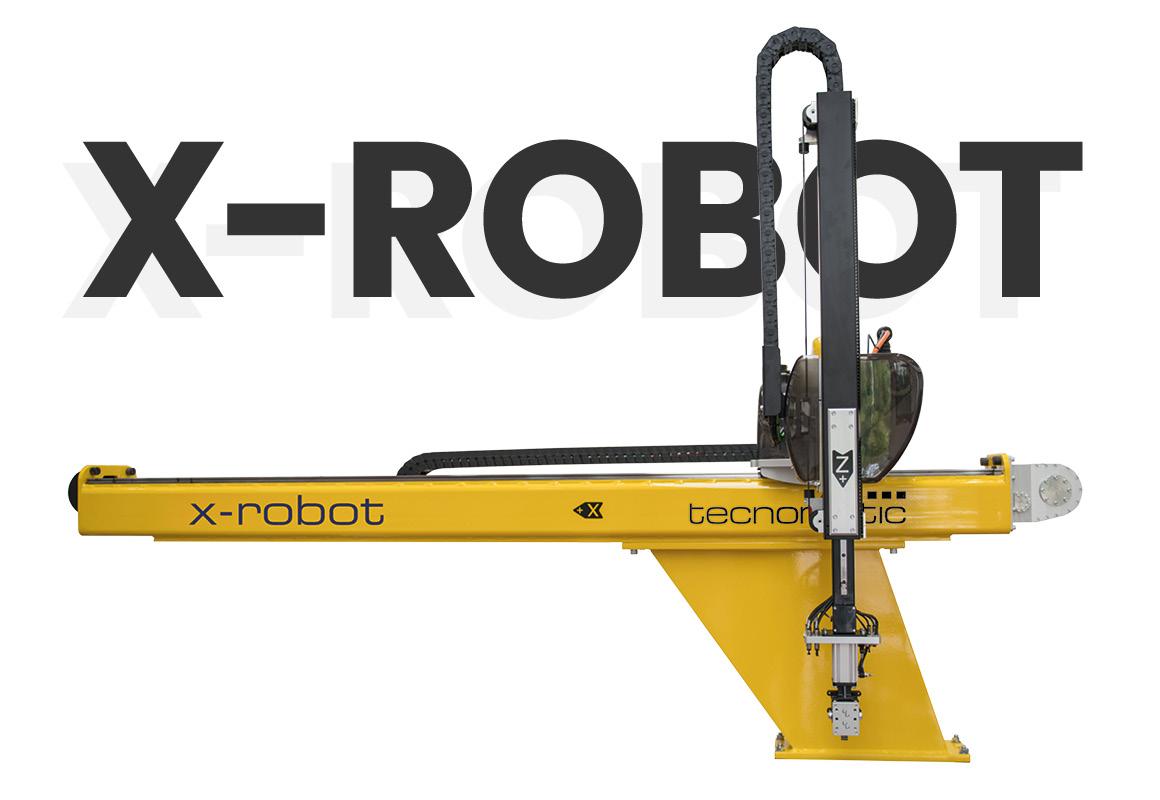

The robot CNC model X-Robot is designed to have a very short cycle time, so that it can be used in the packaging sector and in other cases where the time of entering and exiting the mold needs to be as short as possible.

With a total cycle time of less than 3 seconds, it can replace a side-feeding robot in many cases.

In order to obtain high shaft speeds (up to 5 meters/sec), specific technical solutions have been applied for both mechanical design and software development.

High speed, vibration control and large payload put this robot at the highest technological level.

The CPU is equipped with a powerful programming mode (Free Guided Programming – FGP) with which even very complex work cycles can be easily programmed.

The main structure and the vertical telescopic shaft are made of steel to obtain great structural rigidity.

OTHER TECHNICAL CHARACTERISTICS:

- Applicable to machines from 100 to 350 tons;

- Maximum payload: 6 kg;

- Powerful brushless servo motors on all axes;

- Telescopic vertical shaft in steel;

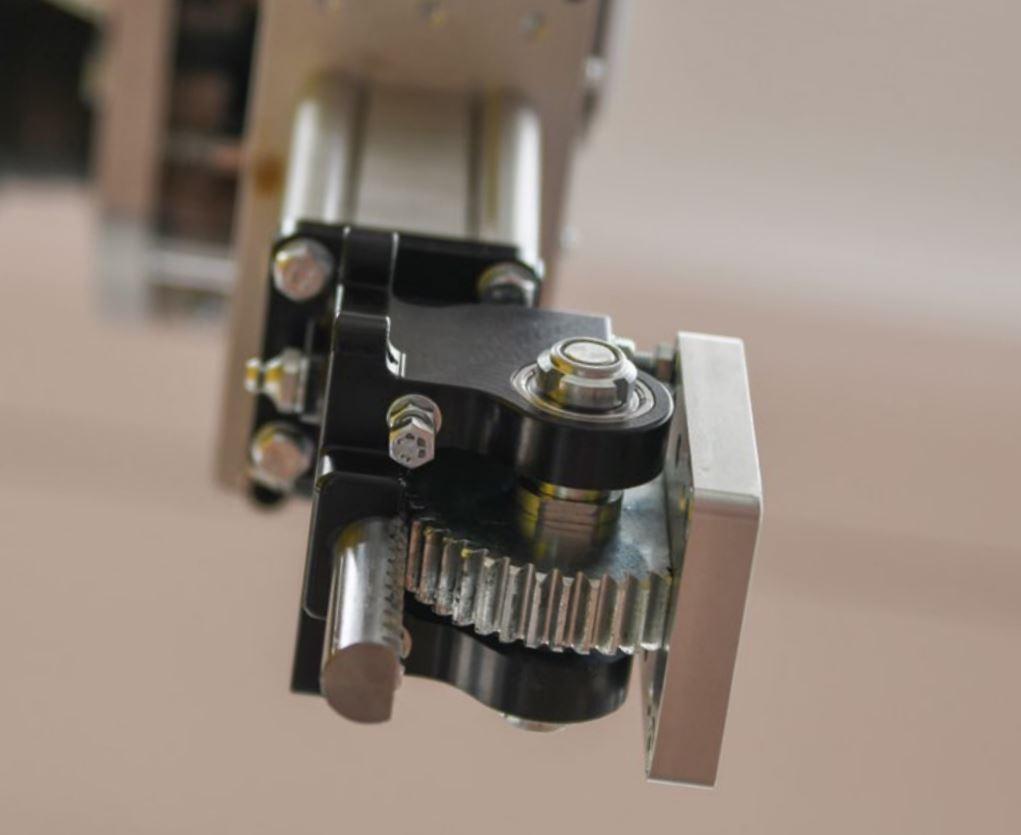

- Axis movements on rectified prismatic guides and recirculating ball bearings;

- planetary speed reducers;

- Axis movements by high-resistance toothed belts;

- Ability to perform movements with torque control;

- Movable programming keyboard with large 10 “touch screen” color display;

- Interpolation and overlap of the movements of all axes;

- Consecutive movements with radius connection;

- Standard on the wrist: two analog vacuum circuits, four pneumatic circuits, five digital inputs;

- Control of the presence of the part by means of analog vacuum switches that can be set directly from the programming keyboard or by photocells;

- Timed output to operate a conveyor belt;

- On the control box: five inputs and five freely programmable outputs to link the robot with other automations downstream of the robot.

PROGRAMMING:

- Free Guided Programming (FGP) allows you to write the work program using already written “actions”, which are in a special library;

- Automatic self-learning of axis positions;

- Step-by-step and delayed implementation of the work program to verify its correctness;

- Program storage on USB memory;

- Numerous palletizing and depalletizing patterns for filling pallets, boxes, etc.;

- Ability to insert different kinds of subroutines into the main program that will run when the right conditions are met (for example, they are used to discard defective pieces, insert interlayers, etc.);

- Possibility to remove the pieces from the fixed part of the mould.

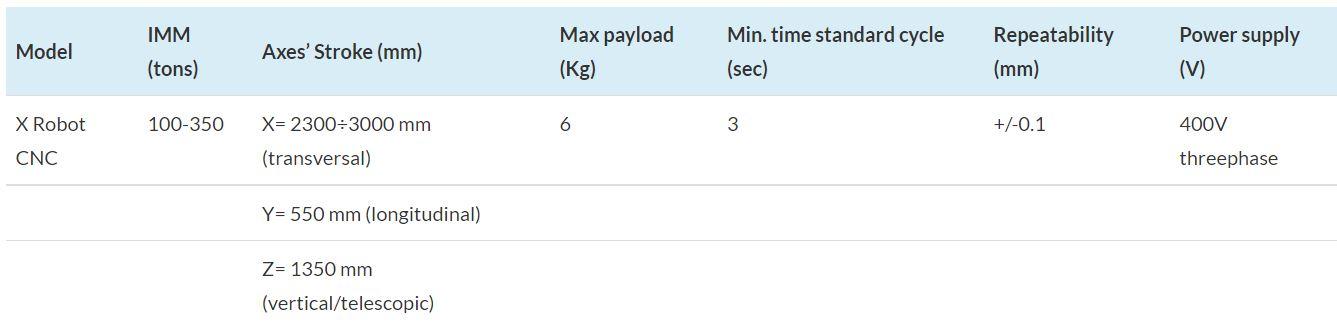

| Fashion model | X Robot CNC |

| IMM (tons) | 100-350 |

| Axes Stroke (mm) | X= 2300÷3000 mm (transverse) |

| Y= 550mm (longitudinal) | |

| Z= 1350 mm (vertical/telescopic) | |

| Max payload (Kg) | 6 |

| min. time standard cycle (sec) | 3 |

| repeatability (mm) | +/-0.1 |

| Power supply (V) | 400V three phase |

- Very short cycle time (Less than 3 sec.)

- High shaft speeds (up to 5 meters/sec)

- High speed, vibration control and high load capacity

- Highest technological level

- Powerful programming mode