The Muehsam depalletizer DP15T is a complete system that automatically empties plastic bags and will measurably improve work in your business.

Operating principle

After the forklift driver loads the pallet with plastic, it is lifted to machine via a chain drive.

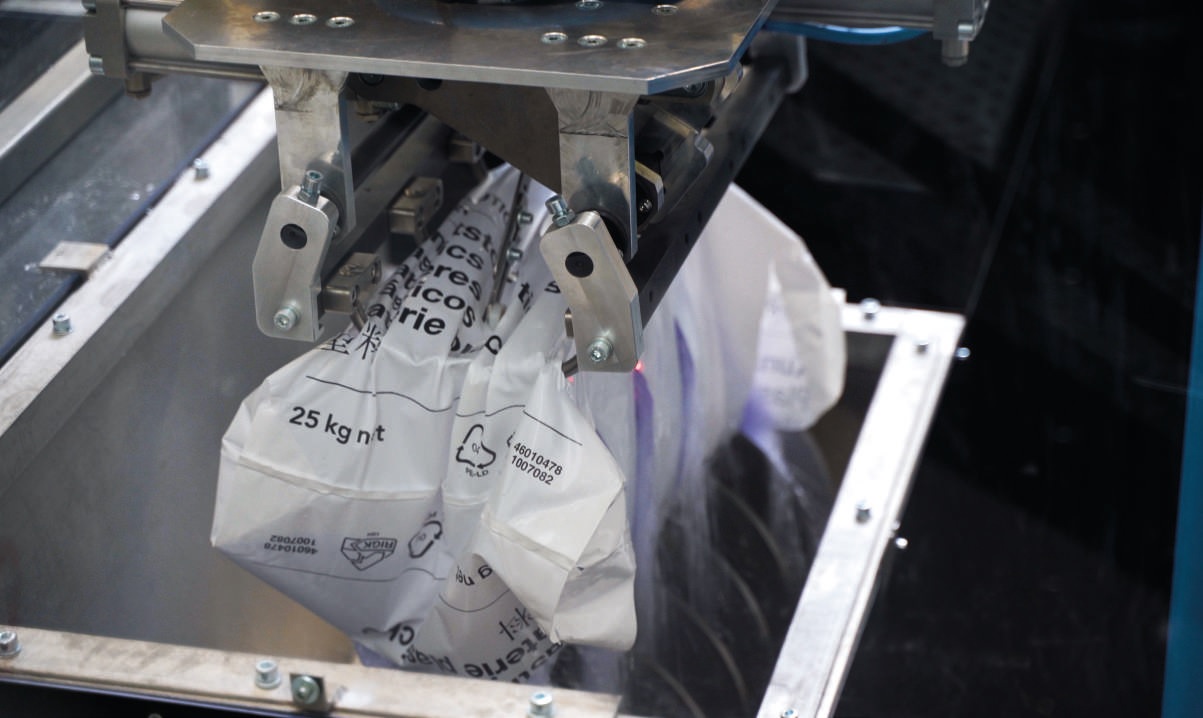

Integrated hooks dig into the bags, transferring the entire layer of the pallet to the cutting section where the bags are cut by rotating blades and the material falls into the intermediate hopper.

To minimize the loss of granules, the bags are additionally beaten with stainless steel rods through an eccentric system.

When The pallet is empty, the operator receives a light and sound signal to replace the pallet with a full one.

Machine configurations:

Performance

Thanks to the use of inverters, the machine is fully controllable, reducing electricity consumption.

Each moving part of the machine is equipped with a speed control.

We have 2 versions depending on performance:

- Adjustable capacity up to 15 t/h

- Adjustable capacity up to 25 t/h

Unloading material

The Muehsam machine is a modular solution and unloading plastic can be adapted to the production character of the company:

- BigBag

- Mobile tank

- Silo (rotary valve + pump)

Loading pallets

Pallet loading is done in 2 versions – semi-automatic (forklift) or automatic.

In automatic mode, the operator places up to 5 pallets on the feeder, which are then automatically moved for further unloading.

Empty pallets are stacked in sets of up to 10 pieces:

- Forklift

- Automatic pallet feeding with a stacker – the ability to place 5 pallets in a row

Method for compressing empty bags

Empty bags take up a lot of space. Thanks to the following solutions, they are compressed and ready for further processing or resale:

- Compactor

- A hydraulic press

- Tank (cone with funnel, transparent walls made of polycarbonate)

- Gutter with handles under the BigBag

- None (we leave empty space for the customer’s basket)

- Mobile tank

Technical parameters:

- Capacity: adjustable up to 15 t/h

- Bag emptying accuracy up to 99.98%

- Machine dimensions: 2800 x 6000 x 3600 (W x L x H)

- Pallet dimensions: 1300 mm x 1100 mm

- Pallet weight up to 1600 kg

- Pallet height max. 2200 mm

- Power supply 3x400V, 50Hz

- IP55 protection

- Compressed air consumption 10 l/cycle 6 bar

- Installed power up to 10 kW without pump

- Automation of the production process

- Increasing production efficiency

- Saving human labor

- Improving work and environmental ergonomics

- Reduction of production costs

- Possibility of expanding the system with a compactor for empty bags and a palletizing system for empty pallets

- Possibility of segment expansion to feed the second material with smooth regulation of the proportion of granules fed