The LITE 1.5T Muehsam depalletizer is a fully automatic system used to empty plastic bags with minimal human intervention.

This is a model with a capacity of up to 1.5 t/h, designed to empty 1 pallet.

Its advantage is its compact design and smaller size compared to the standard large DP15T version.

Operation basics:

After the forklift driver loads the pallet with plastic and selects the location of the bags, the sensor locates the location of the bag on the pallet.

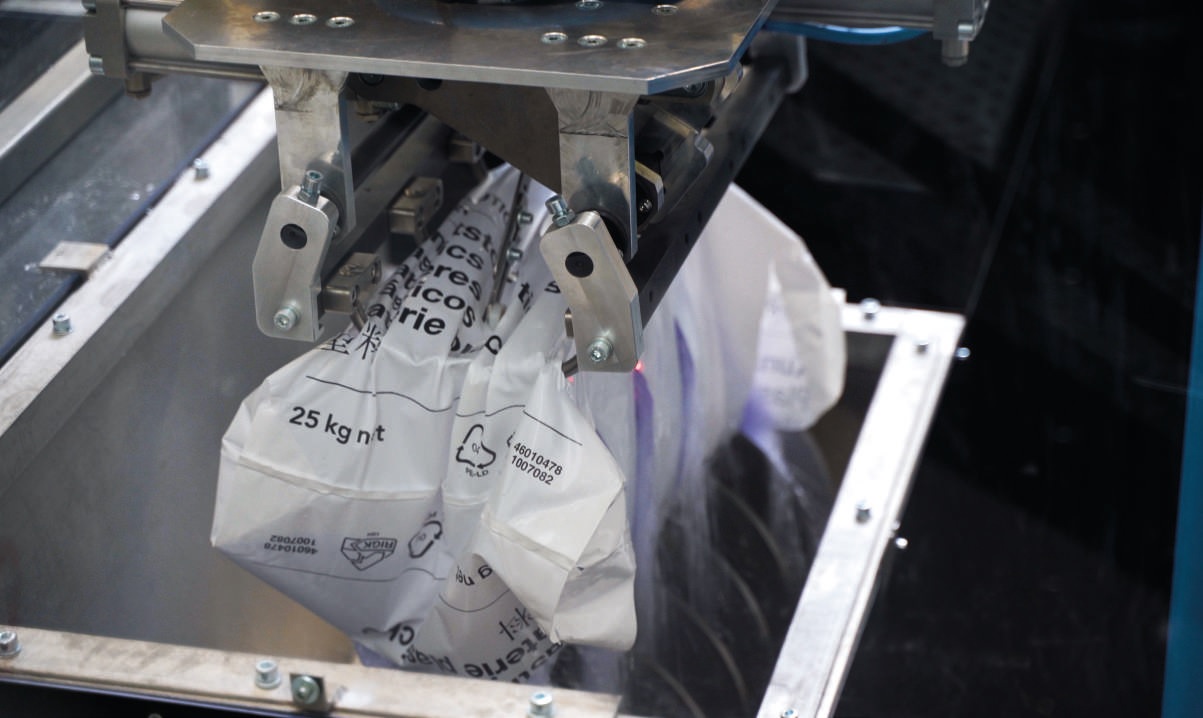

The position of the bag is determined by sensors and the bag is impaled on hooks.

The gripper transports the bag to the cutting section, where the bags are cut by rotating blades and the material falls into the intermediate hopper.

Empty bags are deposited in the empty bag collection section.

Technical parameters:

- Capacity: adjustable up to 1.5 t/h

- Bag emptying accuracy up to 99.98%

- Machine dimensions: 3600 x 2400 x 3300 mm (W x L x H)

- Pallet sizes up to 1300 mm x 1100 mm

- Pallet weight up to 600 kg

- Pallet height max. 2200 mm

- Power supply 3x400V, 50Hz

- IP55 protection

- Compressed air consumption – 15 l (8 bar) / cycle (bag)

- Installed power up to 6kW

Structure of the machine:

- Carbon steel frame

- Grab head equipped with 8 hooks

- Drive of the head controlled by a servo drive

- 10 rotating blades for cutting bags made of hardened chrome steel

- For example, a special mesh in the tank protects against bag pieces entering the granulate transport system

- OMRON process control

- 9″ high-resolution color touch screen for controlling and managing machine parameters

- Safety switch on the switch box

- Safeguards to protect moving parts

Machine control:

- The machine control system is made by Muehsam Solutions for Industry to the highest standards.

- The system is operated via a 9″ touch screen

- Fully adjustable drive speed thanks to the use of inverters

- The components used to build the control cabinet are Omron brand to ensure reliability in every respect

- SEW or Omron motors and gearboxes

- PREMA pneumatics

- Automation of the production process

- Increasing production efficiency

- Saving human labor

- Improving work and environmental ergonomics

- Reduction of production costs