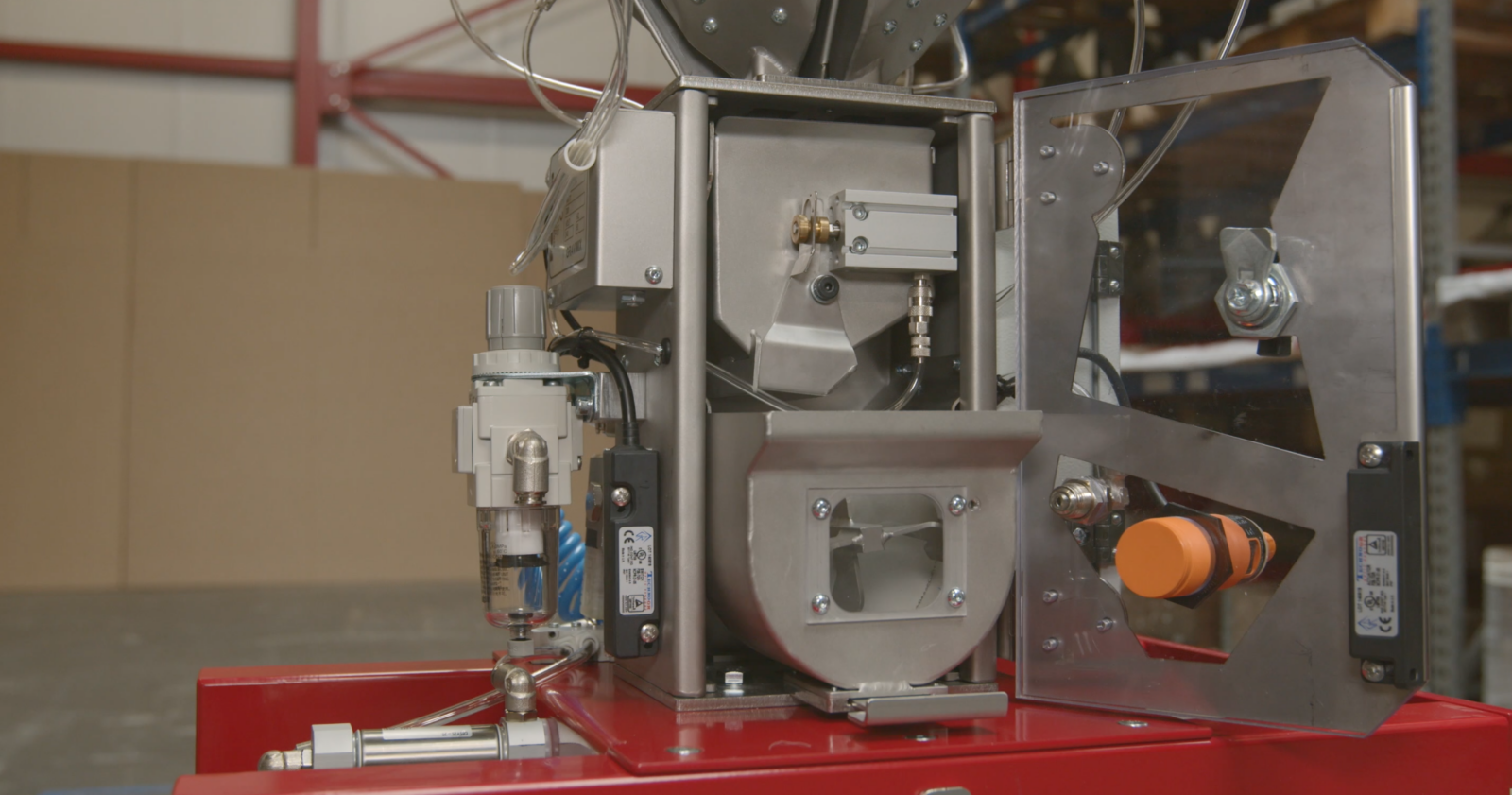

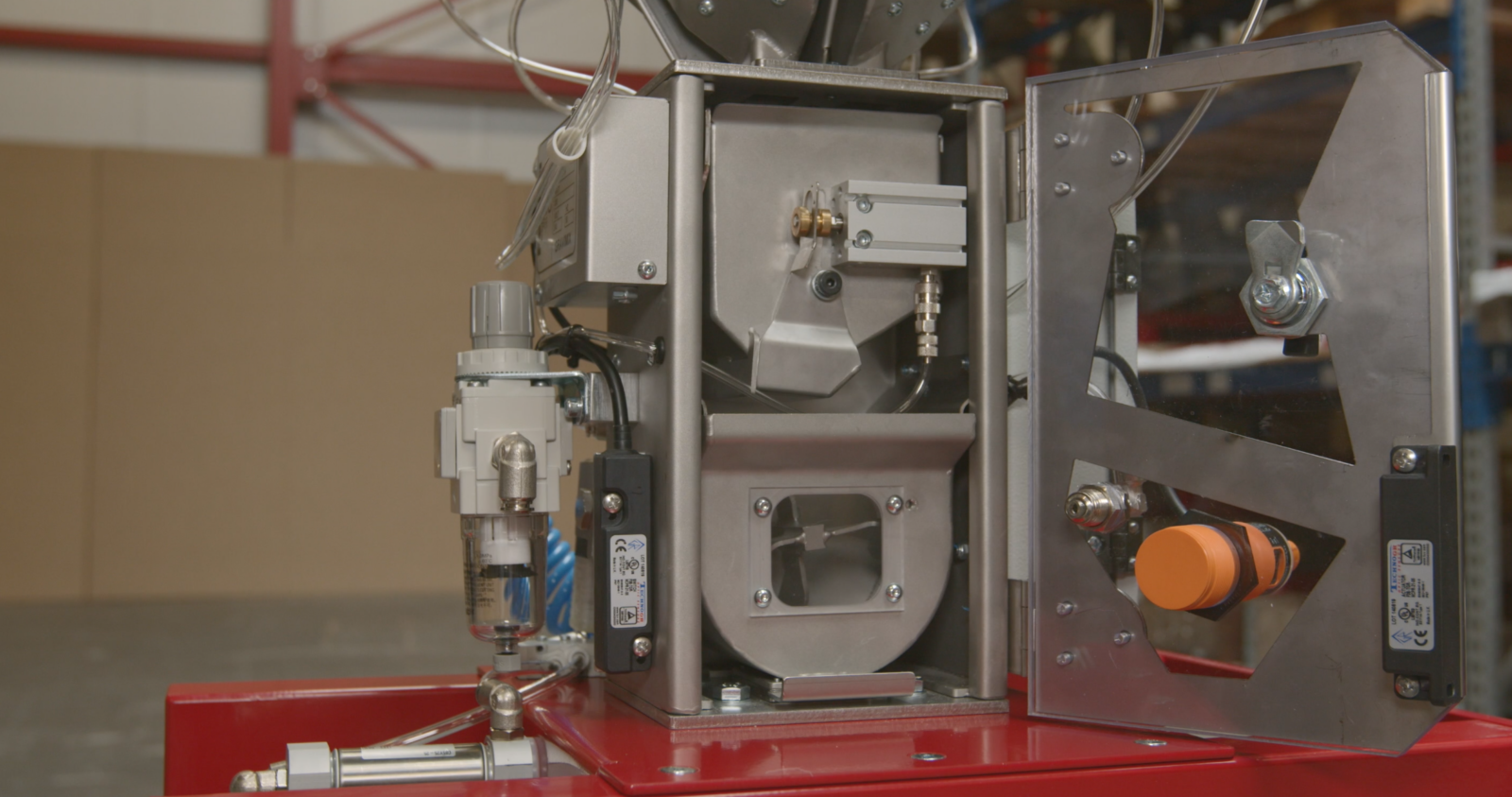

DOSING WITH THE FGB NECS

We have developed the GRAVIMIX Easy Clean System dosing systems for efficient and precise dosing of dry and free-flowing thermoplastic materials. The emphasis has been on minimizing the size and usability as much as possible. That’s why the NECS features our proven Easy Clean System and fits virtually anywhere. This makes this machine extremely user-friendly and developed with the science of practice in mind.

- Max. capacity: approx. 25 kg/h

- Number of components: 2 to 4

- Extended Controls

- Compact and solid

- Easy Clean System

- Max. capacity: approx. 25 kg/h

- Number of components: 2 to 4

- Efficient and accurate dosing

- Easy cleaning system

- User-friendly and reliable

- being able to switch quickly between materials

- Mixing chamber with integrated mixer and shut-off slide is completely removable